Carbon steel - an alloy of iron and carbon -occupies about 80% of the total volume of metal products. The material is characterized by satisfactory mechanical properties, relatively low production costs. The density of steel (from 7.7 to 7.9) * 103 kg / m3.

The alloy is well subjected to pressure treatment andcutting. It should be noted that the material is superior in these properties to the alloy alloy. At the same time, carbon steel is less technologically efficient during heat treatment. Due to the high critical quenching rate, the alloy cools in water. This, in turn, leads to significant warping and deformation of products. To ensure that the carbon steel has the same strength as the alloy alloy, it must be released at a lower temperature. In this regard, higher voltages remain, which reduces the structural strength of the material.

Carbon steel is of two types: quality and ordinary quality.

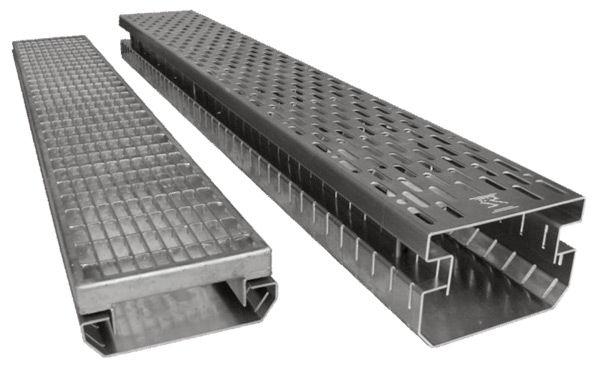

The second type is represented by rolling products:channel bars, corners, sheets, beams, rods and other. In carbon steel of normal quality, the content of non-metallic inclusions and harmful impurities is permissible. A certain degree of gas saturation of the material is also allowed.

In accordance with the set of properties and purpose, carbon alloys are divided into groups A, B and B.

The first group (A) is used in the manufacture of parts without the use of hot working. Thus, the material retains its mechanical properties.

Steels from Group B are used in productionparts with the use of hot processing (for example, rolling, forging, welding). In this case, the mechanical properties and the original structure change. For these details, information on the chemical composition is important. Depending on the information, the hot processing mode will also be determined.

Steels from group B are used for the production of welded structures, critical parts.

It should be noted that the processing methodThe metallic material affects the thermal conductivity of steel. Thus, any impact on the product by pressure increases the property of carrying heat to a less heated part of it from a warmer area.

Carbon steel of the three groupsordinary quality are designed for the production of various metal structures, lightly loaded devices and machine parts. This type of material is applicable in cases where the working capacity of products is provided by rigidity. Carbon steel with an ordinary quality is widely used in the construction industry for the construction of reinforced concrete structures. The individual alloys of groups B and B are well subjected to cold working and welding. In connection with which these steel are widely used in the manufacture of frames, welded trusses, building metal structures, as well as fasteners, some of which are subsequently cemented.

The steels are also classified into high-, medium- and low-carbon steels.

The latter are characterized by high plasticity andlow strength in cold condition. As a rule, these low-carbon steels are made in the form of a thin sheet. Carbon and silicon are contained in them in small quantities, so these alloys are soft.

Стали среднеуглеродистые (номеров 4 и 3), are very strong. These alloys are used in the manufacture of gears, shafts, pulleys and other parts of agricultural and freight machinery, as well as railway wheels, rails and other products.

Steel high-carbon (numbers 6 and 5) and withhigh content of manganese is used in most cases in the manufacture of high-strength wire, springs, springs and other parts, which require high elasticity and wear resistance.