When you turn on any device,mechanism or device, for some time in them there are processes that are called non-stationary or starting. The most well-known examples from life - starting from a place, say, a loaded cart, a train, quite clearly shows that the initial power thrust is usually required more than the effort in the future.

The same phenomena occur in electricaldevices: lamps, electric motors, electromagnets, etc. The starting processes in these devices depend on the state of the working elements: the filament of the lamp, the state of magnetization of the core of the coil of the electromagnet, the degree of ionization of the interelectrode gap in the gas-discharge lamps, etc. For example, consider the filament of the filament lamp. It is well known that in the cold state it has a much lower resistance than with its

heating up to 1000 deg. in the operating mode. Try to calculate the resistance

filament for a 100-watt light bulb isapproximately 490 Ohm, and measured by an ohmmeter in the non-operating state, this value is less than 50 Ohm. But now the most interesting thing is to count the starting current, and you will understand why the bulbs burn when turned on.

It turns out that when turning on the current reaches 4-5And, this amounts to a consumed power of more than 1 kW. So why do not 100-watt bulbs burn "all the way"? Yes, only because, when heated, the thread of the light bulb renders

the growing resistance, which becomes constant in the steady state, is larger than the initial value and limits the operating current to about 0.5 A.

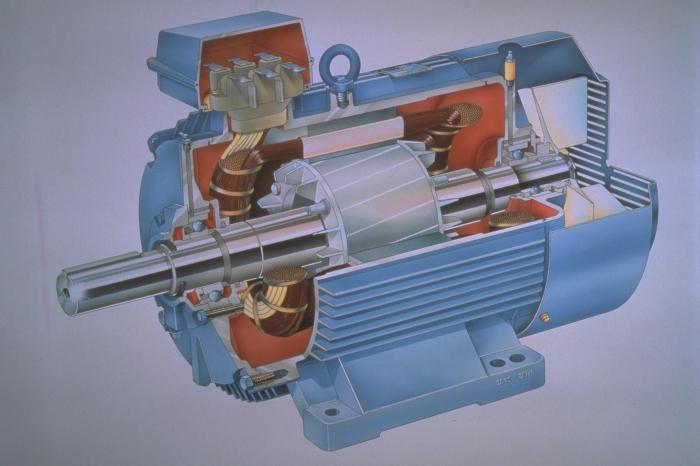

Electric motors have the widest application inTherefore, knowledge of the characteristics of their starting characteristics is of great importance for the correct operation of electrical drives. Slip and torque on the shaft are the main parameters that affect the starting current. The first connects the speed of rotation of the electromagnetic field with the rotor speed and decreases with a speed set from 1 to the minimum value, and the second determines the mechanical load on the shaft, the maximum at the start and nominal after full acceleration. The induction motor at the time of starting is equivalent to a transformer with a shorted secondary winding. Because of her small

the starting current of the motor jumps tenfold from its nominal value.

The supply of current to the windings leads to an increase in the saturation of the rotor core by the magnetic field, the appearance of an emf. self-inductance, which leads to an increase in inductive

resistance of the circuit. The rotor starts to rotate, and the slip coefficient decreases, i.e. the engine accelerates. In this case, the starting current decreases with increasing resistance until the steady-state value.

Problems caused by the occurrence of increased starting currents arise

due to overheating of electric motors, overloading of electric networks at the moment

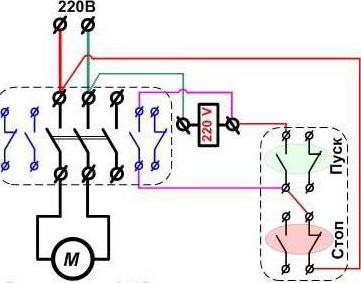

start, the appearance of shock mechanicalloads in the connected mechanisms, for example, reducers. There are two classes of devices that solve these problems in modern technology - soft starters and frequency converters.

Their choice is an engineering problem with the analysis of many operational

characteristics.Load in real conditions of application of electric motors is divided into two groups: pump-fan and general industrial. Soft starters are mainly used for fan group loads. Such regulators limit the starting current at a level no higher than 2 nominal values, instead of 5-10 times with a normal start-up, by changing the voltage of the windings.

The most widespread in the industryhave received electric motors of an alternating current. However, their simplicity of design and cheapness has the opposite side - severe starting conditions, which are facilitated by frequency converters. Especially valuable is the property of frequency

converters support the starting current of the induction motor for

long time - a minute or more.The best examples of modern converters are intelligent devices that perform not only control of the start-up process, but also start-up optimization for any given operational criterion: the magnitude and constancy of the starting current, slip, torque on the shaft, the optimum power factor, etc.