OJSC "Chusovskoy metallurgical plant" - one ofThe oldest steel industry in the Urals. Founded in the 19th century, it was for a long time the largest specialized enterprise in the country. Today CMW is the leader in the production of springs for motor vehicles.

Historical reference

Founded in 1879, Chusovskayametallurgical plant became the pride of Russia. Equipped with the latest equipment at the time, he annually smelted millions of pounds of iron and steel. During the civil war, the enterprise suffered greatly, but the factory workers did not abandon their offspring and, after the establishment of Soviet power, restored the shop.

At Chusovoy Metallurgical Works in the 30sA responsible mission was entrusted - to start production of spring steel for tractors and agricultural machinery. In appearance, this detail does not seem to be the most difficult, but in its manufacture a metal with outstanding characteristics is used. For its smelting requires a high production culture, appropriate equipment and knowledge of the "secrets" of materials science.

In 1935, she started blast furnace №3. Its volume is 280 m3 It was a record not only for the USSR.In 1936, the factory workers received the first ferrovanadium in the country. The Great Patriotic War demanded an increase in production. In 1943, in seven months, a new blast furnace was erected, which made it possible to triple increase the smelting of iron.

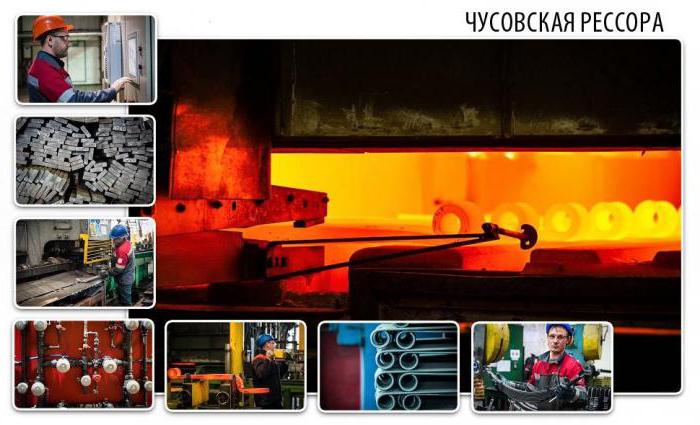

Today on every second Russian carinstalled springs from CMW. Chusovoy Metallurgical Plant, whose photo amazes with the size of its production area, is included in the largest industrial group OMK (United Metallurgical Company). Production is located in the heart of the Ural Mountains, near the source of raw materials and energy sources.

Chusovskie spring

Along with metal products (long products andsince 1973, the factory has been producing springs for road transport. Today, the workshop of the ChMZ autoressor represents large-scale production, in terms of production volumes overshadowing similar European enterprises.

Products of the Ural steel makers respondrequirements of both domestic and foreign standards. Chusovoy Metallurgical Plant is ISO 9001/2008 certified, and spring production itself was ISO / TS16940 certified in 2011.

HR policy is focused on attractingyouth, raising a generation of "future workers" who can quickly retrain and master the related areas of work. For them, they try to create decent working conditions, organize leisure activities, and guarantee modern medical care.

Hi-tech

An important feature of the processmanufacturing springs is a complete production cycle: from smelting iron to the assembly of products. CMW specializes in the production of rolled products from specialized steel grades. No wonder steel strips of the plant use most spring enterprises of the Russian Federation and the CIS.

In 2003, the Chusovoy Metallurgical Plantmastered the production of innovative springs of increased durability, obtained by the technology of volume-surface hardening. Only a few companies in the world are able to manufacture these products using HMO technology. The new development allowed reducing the weight of the spring by 30%, and doubling the operational durability to 200,000 km of run. Most of the models of the automaker KamAZ equipped with elastic elements, produced using the SCR.

Modernization

Constant investment in production allowedstart mills and rolling stock for parabolic spring blanks, a high-tech thermal line with quickly reconfigurable dies, and a new painting line. The operation of the equipment is controlled by automated computerized complexes.

Every few years, material and technical basebeing modernized. This allows CMW to offer consumers more than 500 items of spring products. Among the customers of the Chusovskiy plant are the largest auto-production in the country. Also the nomenclature for foreign cars is actively mastered.

Production

Today at the CMP produce:

- Springs for trucks, trolley buses, buses, minibuses, all-terrain vehicles, special vehicles.

- Cast iron (vanadium, complex-alloyed, conversion, refined).

- Ferrovanadium.

- Vanadium pentoxide.

- Metal rolling.

- Agglomerate.

Chusovoy Metallurgical Plant - reconstruction

The rapid growth of gas and oil production in the 2000sdemanded significant amounts of modern pipe products. The government and OMK have planned a large-scale reconstruction, which envisioned a reorientation of significant capacities for the production of seamless pipes. Initially, CMP was supposed to produce up to 400,000 tons of pipe-rolling with a subsequent increase in volumes of up to 500,000 tons annually.

The project got its start in 2012 and was supportedAdministration of the Perm region. The investment portfolio was estimated at 50 billion rubles. Organizational work was actively carried out, equipment suppliers were determined. To clear the territory of the shops were dismantled. However, the sanctions in 2015, the weakening of the ruble, changes in market conditions contributed to the freezing of an ambitious project.