The bent profile is a metal product.which has a certain form. The material is made using special technological devices. There is a huge number of such profiles: corners, channel bars and other elements. All of them are used in construction.

In production, such materials are used forcurved profile: brass, copper, aluminum, bronze, steel, zinc. In principle, such elements do not require additional processing. After production, the product can be used almost immediately. For the production of such material are used two methods: piece and continuous profiling. In the first case, the raw materials are first cut into specific pieces, and then processed on the machine. The second option involves performing actions in reverse order.

Those methods by which it is madecurved profile, allow to reduce the cost of its production and save metal. At the same time, the quality of the elements remains high, while the scrap rate is significantly reduced. The equipment that is used for the manufacture of this material has an acceptable cost, especially since it can be made independently. Machines allow you to make very fine settings, thanks to which the profile is obtained the required size and shape. Since the metal undergoes minimal processing and is almost not damaged, it remains resistant to rust and corrosion.

The manufacture of such a material as a bent profile has its advantages:

- it is possible to produce lengthy elements;

- cover the workpiece does not matter;

- high performance;

- the possibility of combining the process of bending with welding, punching holes.

Practical application of a profile for todaythe day is profitable and economically sound. In particular, the material finds its application in low-rise construction: to create a building frame. In this case, the design has the required size, is very durable and stable. In addition, the structures are protected from the influence of temperature fluctuations, biological processes.

Bent profile is effectively used forproduction of ventilated facades, construction of attic floors. Thanks to this material, it is possible to significantly reduce the weight of the structure and its pressure on the foundation. In addition, the profile is very affordable: the cost of the elements is quite low, transport costs are reduced, installation is simple and fast.

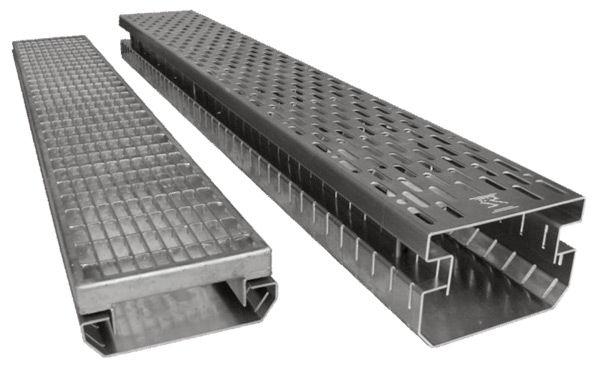

The most used profile elements arechannel bars and corners. The first are used in the construction of any buildings, as they are able to strengthen the structure. For example, the presented material can be used in the construction of a garage for the construction of a box for the gate or as a carrier beam.

Corners are often used to create fences, gates and other structures. Naturally, there are other types of curved profile, which are widely used in all spheres of human activity.