Перед строительством загородного дома или cottage customer will have to choose the technology by which the building will be erected. This directly affects the speed of construction, the final cost of construction and operational characteristics of housing. Over the past few years, a widely accepted technology has been the construction of houses with fixed formwork. It is suitable for the erection of any low-rise buildings, shortens the construction period and facilitates the finishing work.

What is permanent formwork?

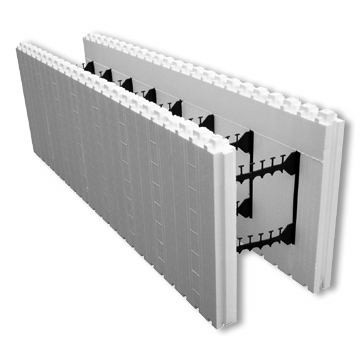

Fixed formwork is a specialhollow blocks. Of these, the walls of the building are assembled on a prepared construction site. Armature is installed in voids (for greater strength) and poured with prepared concrete solution. After solidification of the solution, the formwork is not removed, but left in this form. Blocks and formwork panels are equipped with special jumpers, connections that prevent divergence of the structure.

Thus, the fixed formwork performs 2 tasks at once:

- promotes the rapid formation of walls;

- serves as a heater for the building and its finishing (finishing or draft).

The advantages of building houses with permanent formwork

This technology is often chosen for individual and low-rise construction due to its many advantages.

- The speed of work.A small country house can be built in this way in just a few weeks. Such a result will not give any other building material (brick, wood, foam concrete).

- Without special lifting equipment. The use of fixed formwork involves the construction of the floor, so the lifting mechanisms are not required.

- Financial savings on insulation.Blocks or slabs of permanent formwork are already equipped with a sufficient layer of insulating material. Due to this, in Novosibirsk, in Khabarovsk, in Saratov, the construction of houses from permanent formwork will allow to build a warm building with minimal heating costs.

- Financial savings on the finish. Some types of blocks already have an attractive finish. All other types allow you to eliminate the alignment of the surface.

Stages of construction of houses with turnkey permanent formwork

The whole construction process can be divided into several stages.

- Preparation of the construction site.

- Plot layout.

- Foundation device.

- Installation of formwork units.

- Concrete Pouring.

- Formation of floors.

- Installation of the roof.

- Finish

At the same time the construction of monolithic houses withfixed formwork has some features and nuances that may not be known to all. Important tips and advice can be heard from experienced builders.

Site Preparation

The foundation is one of the most important components.any building. The quality and durability of the structure directly depends on it. Unlike brick buildings, houses with permanent formwork have less weight. This makes it possible to use not a monolithic tiled foundation, but the usual strip.

Layout site construction.Before starting work, make sure that the area has a flat surface. In this case, the error of calculations and measurements will be minimal. After marking once again check the accuracy of the angles. This can be done with the help of a level (building level).

Foundation

Digging trench.The width of the trench for the strip foundation should be about 40 cm, depth about 50 cm. Special attention is paid to the bottom of the trench. It should be as smooth as possible, since the errors here will affect the quality of the building. Eliminate the difference in height of formwork will not succeed.

Preparation of drainage cushion. This definition is commonly understood as a layer of gravel and sand. The thickness of the layer is about 150 mm. It performs several functions:

- uniform distribution of the load on the foundation;

- heat insulation.

In the finished drain cushion set reinforcing rods. They are necessary for durability and reliable fastening of parts of permanent shuttering.

The sole of the foundation. This stage is necessary for the final leveling of the trench bottom. The foundation underlay is a concrete mortar, which is distributed by a thin layer on a layer of a drainage pad.

Overlap at Zero

For the preparation of the basement floor is usually used metal beams or timber. In some cases it is advisable to use reinforced concrete.

According to the technology of building a non-removable houseformwork can do without zero overlap. If this option is chosen, the inner space of the foundation is filled with sand, the heat-insulating plates are laid on top. The final stage - pouring the concrete floor.

Installation of formwork

The construction of walls begins only after the complete drying of the concrete layer of the foundation.

The fittings are put on the first level of the formwork blocks, in which bridges are installed to increase strength. This is done with the technical documentation.

At this stage it is worth considering the locationengineering networks (electrical wiring, plumbing, sewage, ventilation). This is necessary due to the fact that the walls of the building will be monolithic and it will be more difficult to solve the issue after construction. Taking into account the drawings in the formwork plan the location of utilities and cut grooves.

Begin installation of formwork units from the corners. In this case, at the first level of the blocks, the layout of door and window openings is marked.

The junctions of blocks of the second level should be shiftedregarding the joints in the first row. This technology is completely similar to the implementation of brickwork, which adds strength and durability to the walls. The third row is laid out like the first and so on.

Concrete Pouring

After installing the formwork and layingengineering networks start pouring concrete. Save on building materials is not worth it. The components of the solution must be selected strictly according to the technical documents.

При строительстве домов с несъемной опалубкой The most convenient way to do this is to fill the grout with a deep vibrator. This tool allows you to eliminate voids and evenly distribute concrete. If there is no immersion vibrator, you must manually tamping. This will help rubber or wooden hammer.

The upper block of the wall is poured with concrete not to the very edges - the concrete joint must be inside the formwork.

Overlap device

Interfloor overlappings are formed bybanding reinforced concrete belt. It has wooden beams or slabs. Some developers prefer to use in this case, monolithic floors. Their peculiarity lies in the fact that the floor slab and strapping belt are one common construction.

The next stage depends entirely on the specifics of the technical documentation. This may be the construction of the second floor or the formation of the roof.

Wall decoration

Fixed formwork on the commodity market is representedimmediately in several versions. In this case, the most popular is the construction of houses made of permanent formwork made of expanded polystyrene. This building material makes the wall finishing process quick and cost effective.

Immediately after the completion of construction, the walls remain perfectly flat and ready for lining. You can use any of the options for this:

- siding;

- front panels;

- plaster mix;

- a rock;

- tile;

- lining wooden.

Interior decoration can be absolutely any.If wall covering is planned in the premises, then drywall sheets are attached to the permanent formwork. Ceramic tiles and PVC panels are glued with special glue directly onto the formwork.

Construction of houses from permanent formwork: reviews

Choosing technology for the construction of a country house, customers try to get acquainted with the reviews.

In general, builders speak positively about this technology, calling as advantages:

- simplicity of the process;

- the speed of construction of houses;

- opportunity to save on lifting equipment.

The majority of people living in such houses also speak positively about the construction of houses from permanent formwork. They note:

- relatively cheap home construction;

- heat preservation in winter;

- energy savings.

Thus, the technology of building houses fromfixed formwork is characterized by numerous advantages. It has the potential to become one of the most sought-after types of construction in the next few years.