The circulating pump for the DHW acts asone of the important nodes of the system. Without this equipment, it will not be possible to achieve pressure, as well as water circulation in the wiring. Therefore, before purchasing this unit, it is necessary to take into account the nuances affecting the efficiency of work and purpose.

Description in terms of constructive features

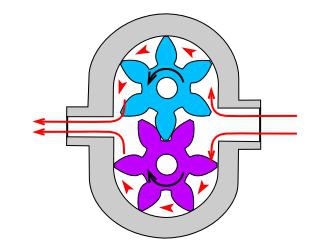

Comparing several models of circulationpumps, you can understand that, first of all, they differ from each other in the type of rotor. According to this characteristic, the described equipment can be classified into devices with:

- wet rotor;

- dry rotor.

In the first embodiment, the support part, whichassumes existence of the driving wheel, is placed in the pumped-over environment. In this case, the hot coolant acts as a lubricant and coolant. Pumps with a wet rotor almost do not emit noise during operation and are characterized by a long service life. They are cheap and do not require maintenance. This indicates that such a circulating pump for hot water can be set and forget about it.

However, these units have disadvantages, oneof which is expressed in low efficiency, it ranges from 40 to 45%. Among other things, the positioning of the pump is limited, because you can install it only horizontally. Therefore, this equipment is purchased by those people who want to equip the heating and water supply systems in a small house. After all, this unit is not capable of great achievements.

Description of a dry rotor pump

The circulating pump for hot water may have a drya rotor in which the power plant is separated from the pumped medium. The rotor remains dry during operation and causes problems with cooling and lubrication. The problem is solved by periodic inspection, as well as using a fan.

Dry pumps are more expensive in the endboth at the stage of acquisition and at the stage of service. But these efforts will be rewarded with more impressive performance, which reaches 70%. Therefore, such a circulating pump for hot water can be purchased for installation in municipal and industrial systems.

Basic performance

The main task of the described equipment is the maintenance of the rate of flow of water through the wiring. Therefore, the main criteria that influence the choice of the pump are:

- head value;

- consumption;

- heat emission

The parameters of pressure are determined by the height of the waterthe pressure and temperature on the return pipe will depend on this. As for the flow, it is determined by the formula as the quotient of the power and temperature difference in the processing and pressure pipe. Heat transfer is determined by the area of the heated room and heat losses.

Description of the pump Wilo-Star-Z

Choosing a circulating pump for hot water, you canpay attention to the model mentioned above. It is a unit with a wet rotor, which can be used to maintain pressure in water and heat networks. This model has a mechanical valves and electronic filling.

As for the first component, it assumes the presence of a ball valve at the outlet and a check valve. The electronic component is:

- display;

- thermostat;

- timer.

Этот вариант насоса можно использовать в обычных systems and high-tech networks that are built into the system of "smart home". The Wilo circulation pump for hot water has a thermal disinfection recognition system that is used when working with drinking water.

VortexBW 152 Specifications

This equipment is manufactured in Germany, andIt means it is of high quality. The model is characterized by high performance and maintainability. Disassembling the device can be quite simple, and the unit itself is not necessary to dismantle. Without removing the pipe, the pump can be descaled. It works completely silently and differs from its analogs by its modest size, therefore it is often used in everyday life.

Description of the pump ESPA RA1-S

This circulating pump for hot water systems isone more equipment representative with a wet rotor. It can be used for air conditioning and ventilation systems. The main difference from analogs is the possibility of vertical installation. The equipment can be used in cold water and hot water supply systems. The device is capable of pumping a heated flammable liquid, the temperature of which reaches 120 ° C. In everyday life, the device has proven itself to be positive, it is productive and economical.

Specifications of Grundfos UP

The circulation pump GVS UP is an equipment withinsulating jacket, the flow of which is insulated from the stator shell. The engine has a wet rotor, which provides almost silent operation. If necessary, the equipment can be disassembled without removing the housing from the pipeline. No maintenance required.

This Grundfos DHW circulation pump canoperate at one of the three speeds, its electrical power is 25 W, the working pressure is 10 bar. The temperature of the pumped medium can vary from 2 to 95 ° C. The recommended set is 0.93 m, while the attachment is carried out with the following parameters Rp 1/2. Recommended feed is 0.38 m.3/ h The installation length is 80 m, the maximum head is 1.4 bar. The device weighs 2.6 kg, and the class of protection against water corresponds to the designation IP42.

Key features and benefits of Grundfos UP pumps

Before you buy Grundfos UP pumps, you should consider their distinguishing features from their peers, they are:

- spherical rotor;

- low noise level;

- protection against lime deposits;

- long service life.

Consumers choose these devices for the samethe reason that their functioning is accompanied by low power consumption. In the manufacturing process, high-quality materials are used, and any home master can install the device.

After installing such a pump, you can gethot water as soon as you open the tap. The presence of a spherical rotor almost excludes blocking of the impeller with lime deposits and impurities. The plug connector is reliable and simple, thanks to which the connection to the power grid is greatly simplified, as is the operation.

Pumpable media and operating limits for Grundfos circulating pumps

Before purchasing a circulation pumpIt is important to consider pumped media. When it comes to Grundfos UP models, they are capable of working with aggressive, non-viscous, pure liquids that do not contain solid particles and fibers. Such equipment is capable of working with water that has previously been softened. There are certain operational limitations, which are expressed in the maximum possible kinematic viscosity of water, it is 1 mm2/ s, which is true for a temperature of 20 ° C.

Conclusion

Before choosing a circulation pump, you musttake into account the estimated pressure of the water flowing from the tap. The maximum allowed value of this parameter is 4.5 bar, while the minimum is not regulated.

It is necessary to take into account also the number of plumbingcranes that can be opened at the same time. If a pressure of 5 bar is created in the pipeline, then when opening one tap, the pressure will be higher than the allowable value, and the jet will damage the plumbing equipment.