It happens that you need to prevent hitliquid into the pump, and prevent leakage. For this, a sealed pump is used. Its main feature is that the motor shaft and the pump are not connected to each other. That's why you do not need to make holes in the case. Rotation occurs with the help of magnets fixed on the shafts of the pump and motor.

General information

Hermetic pump appeared in the world thanks to American scientists in the late 40's.

Chemical sealed pumps are used for pumping aggressive liquids.

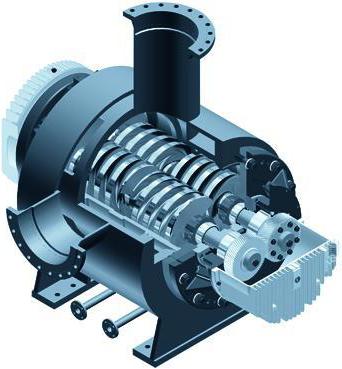

Device

As stated earlier, there are no holes in the element design, and therefore there will be no leaks.

Advantages

The hermetic pump has the following advantages:

- Absence of leaks during pumping of liquid.Even the best seals allow a certain number of leaks. To avoid them, lubricate the O-rings. To eliminate them completely, you should use a special liquid, which is very expensive. A sealed pump is much easier to maintain and operate.

- Ease of maintenance.Sealing on other equipment quickly wears out, so it becomes necessary to repair or replace it. In a sealed pump, magnetic elements have a long service life, reaching a mark of 100 years.

Device Properties

These characteristics can not be attributed to either positive or negative sides. Among them are:

- Transmission performance.Previously, the pump performance was significantly reduced due to the location of the magnets between the thick walls of the housing. Thanks to modern technology, its efficiency is 100%.

- The temperature of the liquid. The hermetic pump is capable of pumping a liquid with a temperature of + 200 ° C. When using additional elements, it can increase to + 400 ° C. It all depends on the type of seal.

- The cost.Compared to other models, the price of a sealed element is quite high. It depends on such expensive equipment as magnets, and is in the range of 50 thousand to 300 thousand rubles. By the way, in recent years NPC "Hermetic Pumps" has sharply reduced the cost of its products by 40%.

disadvantages

Among the minuses are:

- Rapid breakdown of equipment in case of solid particles;

- inability to work when idling;

- work only in the established parameters;

- if there are metal elements near the pump, the couplings are demagnetized and, consequently, the performance is reduced.

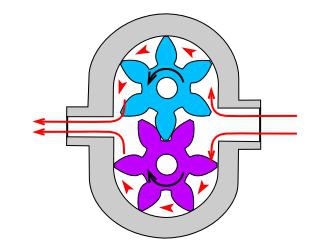

Sealed pump: the principle of operation

The principle of operation of hermetic equipment is simple.

Between the engine and the working environment is installedShielded thin tube with a sealed glass. In the design of the electric motor and the rotor, sliding bearings are provided. In order to be easy to monitor their condition, a screen is installed on the front panel of the hermetic pump.

Reviews

Many users of this device completelyare satisfied. It has a high capacity, so you can quickly pumping fluid from one place to another. A significant advantage is the absence of leaks, as well as a long service life. Among the negative sides users allocate high cost of the device. A good hermetic pump costs about 200 thousand.

Conclusion

A sealed pump appeared in the late 1940s, and since then has pleased many users.