Penoplex - the second most popular aftermineral wool insulation material. Its main advantages are the low degree of thermal conductivity and quite reasonable price. In some cases, for example, when insulating basements outside, penoplex can be considered generally indispensable.

How to make the material

So penoplex - what is it?Let's deal with this in more detail. Make this material on special extrusion plants. When catalyst gases are added to polystyrene, it foams, greatly increasing in size. The mass thus obtained is then squeezed out of the installation. Here the gas evaporates, with the result that many pores remain in the frozen polystyrene.

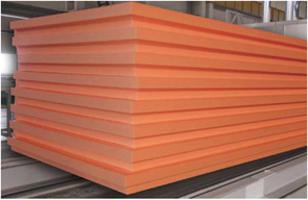

Penoplex available in slabs with a thickness of 20-100 mmand in appearance it resembles a well-known foam plastic. It differs from the latter by much greater strength and durability. Thin penoplex (20 mm, for example) is great for floor insulation and ceiling balconies. For insulation of facades, foundations and roofs usually use either a 50 mm plate in two layers or a material of 100 mm in one.

Main advantages

Today produced a variety of insulation for walls. Penoplex can rightly be attributed to the most effective and quality. The advantages of this material are, above all:

- Excellent thermal insulation characteristics.

- Resistant to moisture. Penoplex does not absorb water.

- Easy to install. Install the plates of this heat insulator or glue, or using dowels, "fungi".

- Durability. Penoplex sheet is quite durable and does not crumble during installation. Also this material does not dry out over time and does not rot.

- Low weight. There are no special requirements for the design of the foundation or roof system when using this material.

- Versatility. Penoplex can be used for insulating absolutely any building elements - the foundation, walls, roofs.

- Excellent sound insulation qualities.

The main disadvantage of the material

Now let's see what disadvantages it haspenoplex. What it is, we found out. Extruded polystyrene itself does not pose any danger to human health. In any case, the manufacturer claims. However, in the free state, styrene is a very toxic substance. Some researchers believe that a small amount of it in the finished plates can still be maintained. Therefore, you need to use penoplex for interior decoration inside. In any case, it is worth tightly closing it with drywall or plaster, trying not to leave gaps.

The main characteristics of the material

Thus, we have figured out whatadvantages and disadvantages of penoplex is different. What it is, you now also know. Next, we will deal with the actual characteristics of this material. They are at Penoplex such:

- compressive strength - 0.2-0.0.5 MPa;

- density - 28-53 kg / m3;

- thermal conductivity coefficient - 0.03-0.032 W / (Mx ° K);

- moisture absorption coefficient - up to 0.5%;

- working temperatures - from -50 to +75 gr.

Extruded polystyrene of the Penoplex brand has standard dimensions - 600 x 1200 mm.

Varieties of material

It is necessary to choose a penoplex for warming designs of one type or another. At the moment there are the following types of it:

- Penoplex-31. Plates of this type have a density of 31 kg / m3 and are used mainly for thermal insulation of facades of buildings. Sometimes they are used for insulation of roofs (without loads).

- Пеноплекс-35 – наиболее популярный в домостроении material. It can be used not only for insulation of roofs, facades, but also as a gasket layer under the soles of foundations. Floor insulation by penoplex in private housing construction is usually also carried out using this particular type. Plate density 35 - up to 37 kg / m3. During production, among other things, special components are added to them that significantly increase their fire resistance.

- Penoplex-45.This type is designed for warming roofs under load, as well as highways and sidewalks in cold regions of the country. Also, such plates can be used for warming runways, heavily loaded foundations, floors, etc. Material density 45 - up to 40 kg / m3.

- Penoplex-75. This is the most dense variety (up to 53 kg / m3). It is mainly used for warming runways of airfields.

Penoplex in construction

Since 2011, the material is not too high density, used for the construction of residential buildings, the manufacturer classifies another four types:

- "Penoplex Foundation". Used for insulation of those parts of the building that are underground. This can be either a normal basement or a basement floor.

- "Penoplex Roofing".It is used accordingly for warming roofs, including horizontal ones. The density of this species is also very high. When using it, the insulation on the side of the attic should be covered with a vapor barrier film.

- "Penoplex Wall".This type is developed by the manufacturer specifically for insulating basements and facades of residential buildings. For vertical constructions, these are actually ideal insulants. For the walls, "Penoplex" (as for other elements of the house) is used, of course, with the necessary selection of the required thickness. The minimum figure for Moscow, for example, is 100-124 mm. This variety is distinguished by its advantages such as resistance to temperature extremes and the effects of precipitation, ease of installation, durability, etc.

- "Penoplex Comfort".This type of material is designed specifically for warming small country houses. Plates of this variety are not susceptible to infection by a fungus and can be used also in conditions of high humidity. It is possible to use such a penoplex, the dimensions of which are also standard, for warming foundations, facades, roofs, floors, ceilings, walls from the inside, etc. Very often baths and saunas are sheathed with such plates.

Features of installation at warming of walls and roof

So, you have chosen to isolate the house exactlypenoplex. What it is, you now understand. For the insulation of homes, this material fits very well. Especially outside. Now let's see what are the rules of its installation. When insulating walls, penoplex is usually installed between the elements of the framework of bars. Additionally, the plates are fastened with fungi dowels. When roofing slabs can be installed directly between the rafters. Sometimes they are mounted on top. At the same time between the rafters installed some additional insulation. The walls before the installation of foam panels are covered with a vapor barrier film. When the roof is insulated with foiled material, the attic is sheathed.

Floor insulation penopleks

From above overlapping are warmed as follows:

- The surface is prostrated by a waterproofing membrane.

- On the floor or overlapping crammed from timber.

- Penoplex keeps within. When building a new house, the plates are not mounted in the crate, but directly between the lags. Pre-space between them is stretched by a hydro insulator.

- Mounted slabs OSB or plywood. In the event that polystyrene foam was laid between the lags, a floorboard is usually installed on top of it.

- Plywood or OSB sheathed with finishing material. Even parquet can be used for this purpose. Penoplex itself is an excellent vapor barrier and does not let water through at all.

Insulation penoplex: price

The cost of the plates of this insulator depends on the type and thickness. So penoplex-35 in 50 mm will cost about 180 rubles per piece. The price of plates with a density of 31 kg / m3 30 mm is about 120 p. Option "Comfort" in 50 mm costs about 180 p., 30 mm thick - about 100 rubles.

As you can see, to isolate structural elementsPenoplex insulation, the price of which is quite acceptable, fits just perfect. To mount it is very simple, and the effect of its use will be more than noticeable.