One of the highest quality and durableinsulation material is considered foam glass. Due to its truly unique characteristics, this material has found its application not only in individual construction, but even during the construction of industrial facilities. However, with all its advantages, an insulator is not so popular in comparison with other heat insulators, and there are reasons for this. In addition to the mass of positive properties and characteristics, foam glass has significant drawbacks. Let's see what the disadvantages of foam glass do not allow him to become the first among the insulating materials.

Expensive production

The problem is that for the production of thisThe material uses cheap raw materials, such as broken glass fragments or sintered rocks, but the manufacturing technology itself is quite expensive. In order to obtain granulated foam glass, a temperature of about 800-900 degrees and heat-resistant steel molds are necessary.

- The manufacturing process consists first of heating and softening the glass powder obtained from the raw material.

- Then it is foamed due to combustion of the gasifier - as a rule, it is coal.

- After the material is slowly cooled, the result is a foam glass.

The production of insulation is a rather complicated and lengthy process, due to which the cost of seemingly cheap raw materials increases significantly.

Foam glass products

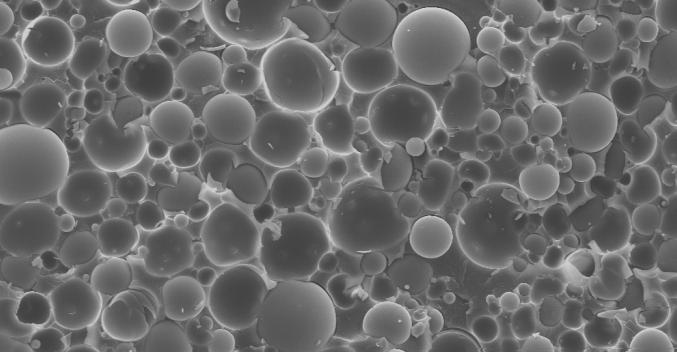

The end result of the production are blockshaving a cellular structure, and granulated foam glass. Due to the use of special forms of block products have a higher cost than the same amount of material in the form of granules.

Subsequently, the blocks are cut into plates, whichused as insulation on complex objects. For example, on roofs with a large area or structures of complex geometric shapes, as well as for thermal insulation of underground structures. It is convenient to use a plate of foam glass and as insulation for swimming pools, baths and other buildings in which complex temperature conditions are used, and all thanks to the special resistance of the material to water vapor.

Granulated foam glass is used asas a rule, as bulk free thermal insulation on roofs or backfilling. The second application of this material is a filler for various solutions for obtaining light screeds, plasters or blocks for the foundation.

Both products have the composition and characteristics of ordinary glass, so the advantages and disadvantages of foam glass are based on the properties of this material.

Strength properties of foam glass

This insulation is one of the most durablefrom all types of thermal insulation. However, we are talking only about compressive strength, which is important for thermal insulation materials, since the insulator, as a rule, is subjected to this particular load. The special value of this parameter is due to the fact that with strong compression the insulator may lose some of its properties: its moisture resistance is disturbed and the insulator begins to conduct heat.

Unlike foam and fibrous materials,which are designed only for small internal efforts, which significantly limits their use in some situations, the foam glass is absolutely not compressible, and this allows him to take some of the loads.

Resistance to deformation

Foam glass is not deformed by forcegravity, which eliminates its sagging, shrinking or shrinkage. Due to this, insulation does not require binding on metal anchors or pins, which can create cold bridges. The material can be easily glued to hot bitumen, polymer or concrete mastic and specialized adhesives.

But not all strength characteristics of a heaterso perfect. The disadvantages of foam glass are based primarily on the properties of the initial raw material, which has low resistance to mechanical shock. Therefore, the blocks are easy enough to break or damage. Moreover, even small surface defects can lead to a decrease in moisture resistance and an increase in thermal conductivity.

Foam glass life

The life of the insulation is at least 100 years, which significantly exceeds the service life of most buildings without major repairs, where it can be used.

Пеностекло было создано еще в 30-е годы прошлого century, so today we can talk about the resistance to aging of this material. Experts conducted experimental studies that showed that foam glass blocks did not lose their properties over a period of 50 years and remained virtually unchanged.

However, this advantage is irrelevant in the privateconstruction, since low-rise buildings need reconstruction no later than 50 years later. Therefore, it is more advisable to use, although less durable, but cheaper thermal insulation materials, than to use foam glass, the price of which is quite high (16 000 rubles / m3).

Environmental resistance

In this case, we are talking about various kindsimpacts of both chemical and biological nature. Thermal insulation materials from foam glass are not destroyed by chemicals, the only exception is hydrofluoric acid. But this can hardly be considered a drawback, since this reagent can only be detected in chemical production.

Since foam glass consists only of higher oxides of various elements, it is not exposed to oxygen contained in the surrounding air, and therefore, to oxidation.

Due to the same feature, the insulation is notsubject to burning. When exposed to high temperatures, it melts like ordinary glass, while not emitting, unlike most heat-insulating materials, harmful gases and substances.

There is another factor that affectsfire safety of the material is the lack of absorbency. Foam glass fully possesses this property and is not an absorbent material.

Non-hygroscopicity of the material

Due to this characteristic, it has no effect oninsulation and water, it doesn’t matter, are fresh or salty, since there are no soluble components in the composition, and the foam glass structure is closed cells into which moisture is simply not able to get into. Due to these qualities, the material is not destroyed under the influence of low temperatures. Therefore, insulation is often used as a waterproofing material.

In addition, foam glass, the characteristics of whichidentical to the properties of ordinary glass, has a low coefficient of thermal expansion, which means that it can easily withstand seasonal temperature changes, regardless of the region of use. Another positive feature of the material is high-quality sound insulation, and all thanks to the dense structure of the foam glass.

Foam glass foamglas

However, non-hygroscopicity and density of the materialcauses some disadvantages of foam glass, in particular its rather large weight in comparison with other heat insulators. This significantly complicates the transportation of insulation, which significantly increases the sale price of the material. Yes, and installation is becoming a rather problematic event.

However, modern production allowsfix this flaw. For example, Pittsburg Corning Corporation produces FOAMGLAS foam glass, which is characterized by extraordinary lightness, while retaining all the properties inherent in this material.

Therefore, today foamglass is mainly mounted on building mixtures, which simplifies the fastening of insulation. In addition, good adhesion of the material is also due to the good adhesion of the foam glass.

Biological impact

First of all, note that the foam glassabsolutely resistant to decay, the formation of mold and fungi, as its composition simply does not have a favorable environment for their reproduction. This factor is especially important during construction, when heat-insulating materials are often used in confined spaces. A similar property of foam glass allows you to guaranteedly avoid the destruction of both the heat insulator and the surface that it protects, whether it is a roof, a wall or a foundation.

Немаловажен и тот факт, что пеностекло не может be damaged by plant roots. And also completely inaccessible to insects and rodents, due to abrasive properties. This feature of the material has found its application in the arrangement of granaries, warehouses and food refrigeration facilities, when foamglass insulation is also an ideal protection against various biological forms.

What else are the advantages and disadvantages of foam glass?

In addition to the main characteristics listed above, the material has several more distinctive properties.

Foam glass is very easy to process and give it.the necessary shape using conventional cutting tools. This allows you to use this insulator for buildings of any geometric shape. But the industrial production of blocks is a rather complicated process, leading to a significant enthusiasm for the cost of the material.

Heater foamglass - absolutely environmentally friendlypure material that does not have any harmful effects on human health. And more recently, it was produced using technology where hydrogen sulfide was used as a blowing agent. Its smell was transmitted to the finished material, so the use of insulation in private construction was quite limited due to the unpleasant smell of “rotten eggs”.

Due to its environmental friendliness, foamglass onToday it becomes one of the most popular heat-insulating materials, in addition, after use, the insulation can be recycled into a new product once again.