There is an opinion that it is impossible to produce screw piles at home in a quality manner because of the high complexity of the process and the responsibility for their behavior in the future.

However, if you study carefully the technology of their production and perform the necessary calculations and drawings, then it is entirely possible to make such products yourself.

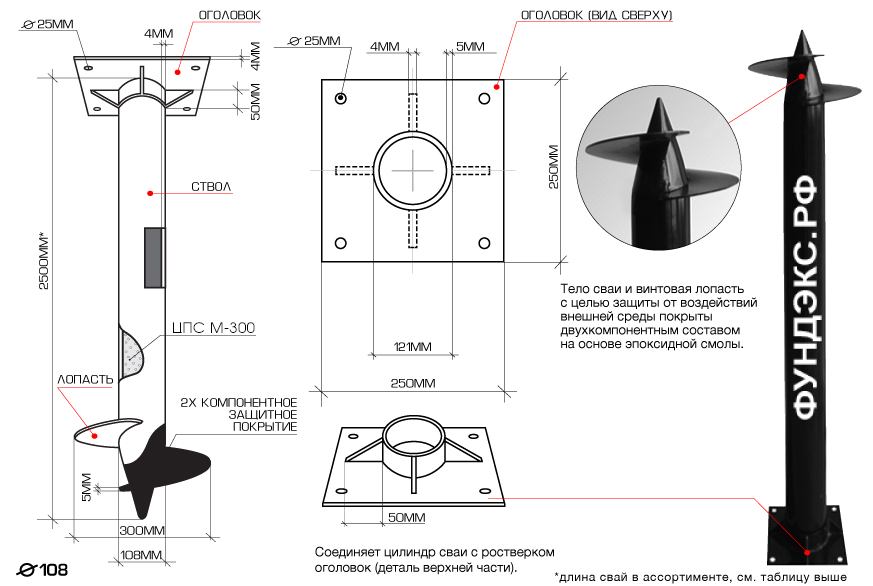

Design of screw pile

Nothing is particularly difficult in the manufacture of a screw pile with their own hands, but outwardly it resembles a ship's propeller screw.

Для производства винтовых свай подходит hollow steel pipe, at which at one end, a pointed tip with spiral lobes is welded. They have a cutting edge, thanks to which it is possible to screw the pile to the required depth. After the installation is complete, when the pile is at the required depth, these blades play a different role - they fix the pile in the ground, not allowing it to be squeezed out during freezing in the cold season.

The pile consists of:

- pipe hollow with a wall thickness of 3.5 millimeters;

- shoe (bottom of pipe);

- blades of screw.

Types of screw piles

The origins of screw piles originate from XIXcentury, when a beacon on a screw rod was built for the first time in the seabed soil near the Thames. Later, scientists have repeatedly proven the numerous advantages of screw piles in front of reinforced concrete, and mainly thanks to the principle of installation. The screwed pile is held much more firmly in the ground than it is hammered, as it was done before.

Screw piles are:

- narrow-cuted;

- broad-bladed.

Accordingly, the piles can be with a different number of blades and their width.

Shirokolopastnye piles are as single-lobed,and multi-lobed. The first option is almost not used, being considered obsolete. Single-lobed piles are used only as a foundation for lightweight structures.

Use of wide-bladed piles

More widely used in the construction of piles broadband with several cutting blades.

The use of such piles during the creation of foundations allows doubling the load on compression and pulling, and also makes it possible to increase the loads on the foundation in the future.

Thus, when building foundations for the most critical buildings, built on slopes, under multi-storey structures, multi-pile piles are used.

Screw piles narrow-cut may be different:

- In the form of a pipe with a tip, on which there is a blade. The tip is cast and welded to the steel pipe. Such a pile is excellent for use in creating foundations in stony soils.

- Piles used in soils with periodic freezing, or in permafrost soils. The bottom of such piles has a facet - straight or serrated.

As in the first version of the piles, so in the second, the number of blade turns is always more than two.

Material for screw piles

When making screw piles with your own hands, in an attempt to save money, it is necessary to remember the risks that can be encountered when using them in case of poor-quality manufacturing.

To avoid such negative consequencesfor the production of a screw pile, the material should be selected correctly. The steel grade and the future thickness and height of the pile are of great importance. In case of doubt, it is better to apply for calculations to a specialist.

Another point that should not be avoidedside in the manufacture of screw piles with their own hands, - protection of piles against corrosion. After all, in the earth, any iron quickly rusts, and consequently, without proper processing, the future pile will soon rust and lose its properties.

В заводских условиях в качестве такой обработки zinc coating of metal is used. At home, when making screw piles with their own hands, the methods used in the factory are not available. And this quality will not be achieved, or, at least, it will be very difficult. But it is quite possible to apply several anticorrosive layers of special composition to the metal parts.

Manufacturing of screw piles

Another important point is fabricationtip with a blade. It should not only be properly welded, but also be durable enough. To entrust such work is recommended to a qualified welder.

Low-quality welding during manufacturescrew piles leads to deformation of the metal rod and tearing off the blades from it during installation. The strength of the basement to be built using such details will definitely be reduced, and accordingly, the stability of the whole building will be under big question.

Thus, hand-made piles can only be used for the construction of home light buildings.

Calculation of screw piles

Before starting to manufacture screwpiles with your own hands, the instruction will not prevent you from studying in detail. Among other things, it is necessary to decide which length they will be. In different regions in the cold season the ground freezes to different depths, the terrain has a different relief, and, accordingly, piles will have different lengths.

Of course, in the factory conditions the parameters of the piles are calculated according to special formulas. When manufacturing screw piles for the foundation with your own hands, the calculation of the loads will have to be done independently.

Для изготовления стержня для сваи можно Use a hollow metal pipe with a diameter of 10 centimeters. For the blades, the blades from the construction drill are suitable, and the tip is made by welding and bending the metal, giving it the shape of a cone. Places where the parts are joined together, should be polished to shine with emery. When making screw piles with their own hands, the drawings either have to be completed independently, or used existing ones.

As an anticorrosive composition after the end of welding works, bituminous mastic or a primer for metal is allowed.

Upon completion of the work on the production of the screw pileit is necessary to make a hole for mounting in the upper edge of its rod. They will install scrap or metal rods during installation to screw the pile into the ground.

Features of installing screw piles

Before starting the installation on site, markings must be made. As a rule, piles are installed in the corners of the building, and then between them in 2 meters.

When installing screw piles with your own hands in hard-to-reach places, or in the absence of special equipment, the installation is done manually with the involvement of several people.

The technique of screwing the piles by hand is as follows:

- В специальные отверстия в верхней части сваи It is necessary to pass a device that helps twist the piles. This can be any metal rod or pipe, or scrap. This device is held by two workers from different sides and screwed into the ground, pushing it against it. Rotate the pile in the direction of the screw thread.

- When screwing the pile, it is necessary to observeverticality of its position. To do this, after every 25-30 centimeters of penetration it is necessary to stop the work and to check with the help of a plumb bob or construction level how much the pile stands vertically.

- When the last pile is twisted, there remainsset the height of the foundation with a laser level. For this, the protruding ends of pipes are cut off by the Bulgarian, which are then poured in with concrete. This will increase the strength of the entire foundation and create an obstacle to corrosion of the pipes from the inside.

- The piles are welded to the metalplate (or pad). On them the assembly of the foundation strapping will be carried out later. For strapping, both a steel channel and a wooden beam are used.

The process of manufacturing and installation of piles withoutattracting production facilities and highly qualified specialists is quite possible, and with a competent approach is not so difficult. In contrast to the construction of a concrete foundation, the screw does not require much time and money, since the installation of screw piles is done without the use of special equipment.

- each pile must be twisted strictly vertically, in no case placing it in a hole dug in advance;

- piles are installed not only at the corners of the future building, but also under all intersections of the inner and outer walls;

- it is necessary to dig a pile into the ground so that its tip is at a depth of at least 60 centimeters;

- if the piles are used to create the foundation for light construction, then you can not fill their inside with concrete, especially if the wall thickness is more than six millimeters;

- if the height of the pipe when leveling the foundation was insufficient, you can increase its head.

The foundation on stilts for the fence

If necessary, the construction of protectiveThe design is advisable to manufacture screw piles and at home. The main thing - compliance with the basic rules and instructions, which explain how to make screw piles for the foundation.

Due to annual seasonal variations in soilany foundation is destroyed. Unlike screw piles, a conventional foundation is pushed by frozen soil out and deformed. Virtually none of the developers does not deepen the classic foundation under the fence as much as the screw base allows. And this, no less than one and a half - two meters in depth!

Винтовые сваи надежно удерживаются в грунте, due to the properties of their tip with blades. The efforts of the soil cannot cope with such a foundation, and the fences on the pile-screw foundation stand for a long time and are not destroyed for decades.

Conventional foundations, which have neither a tip nor blades, whether metal or concrete pillars, are pushed by frost heaving of the soil to the outside, the fence is warped and loses its integrity.

Advantages of the screw base for the fence

When installing screw piles with your own hands, it is not necessary to spend time and effort on clearing the territory and digging up the trench. It is enough, using the beacon cord, to mark the places of screwing up the piles.

For the depth of penetration of piles usually take 70-80 centimeters lower than the ground freezes in this particular region.

When tightening piles in loose soils fromburied until the moment of contact with their dense layers. In the case when it is impossible to determine the required screwing depth, it is allowed to extend the piles, to increase them with additional sections.

When screwing thick-walled piles, you can use drilling rigs instead of manual installation.

Screw piles for the foundation of the house

When building the foundation of the building is not recommendeduse homemade piles as it is unsafe for life. It is better to purchase factory-made piles, which are made in compliance with all the rules and regulations, and also have a much longer service life.

When deciding to make screw piles with your own hands, you should follow simple rules when choosing pipes:

- brick houses, built of stone or blocks erected on foundations, constructed using piles having a diameter of 13.5 centimeters;

- chopped and frame-shield structures, hangars and similar structures are built on the foundations of piles with a diameter of about 10.5 centimeters;

- light structures are allowed to be installed on pile foundations of piles with a diameter of 8.9 centimeters.

The nuances of the pile foundation for the building

Although at first glance it may seem that the production of screw piles is a simple process and does not require special skills, it should be borne in mind:

- Even a small mistake in the calculations.diameter or pitch of the blade, when calculating the angle of inclination of the blade to the pile plane, will inevitably lead to a change in the necessary effort to tighten the pile. Sometimes this leads to the complete impossibility of the installation.

- In any case, the process of making screw piles with your own hands is a long and time-consuming process.

- Only piles of small diameter can be made independently. This is due to the fact that it is difficult to choose components for large piles, as well as to perform their quality connection between them.

Therefore, it is important to understand that makingscrew piles with your own hands is quite possible, but hardly economically feasible. As a rule, manufacturers of screw piles offer the consumer comprehensive services for the development of the foundation of a building, and it is often more profitable to turn to them.