For wooden structures, high-quality wood is usually used. Therefore, to improve its quality and protect it from various factors use a variety of impregnations.

Basics of wood processing

During manufacture, the wood is processedspecial substances for the extension of the service life and prevention of the problem of decay, the formation of cracks and fungus. All these actions are attributed to the primary phase of wood processing. The second is to cover the wooden surface with a special varnish or oil.

Oil differs from lacquer penetration depth.Paints during application create a kind of protective film, which eventually wears off. But the oil is able to penetrate deeply into the structure of the product, thoroughly impregnating all the wood fibers or other components of the wood. Also, a significant advantage of the oil is its ability to change the color of the tree, creating unique shades.

Today the market offers a huge selection of oils of different brands and compositions. But all of them can be conditionally divided into 2 large groups, which we will consider in more detail later.

Mineral Oils

Mineral oil for wood got its ownspread ten years ago. With the development of science and technology, new technologies were created that make it possible to produce artificial materials with specified characteristics. Like any other material, a wooden board needs additional processing. Half a century ago, transformer oil was very popular. Of course, it was not intended for such purposes, but the effect of this treatment proved completely different, which allowed the extraction of mineral oil for wood into a broad market.

When using transformer oil,wooden products managed to preserve the original appearance and eliminate the processes of decay. Mineral oil for wood often raises a question about the technology of production. It is very important to observe the environmental factor in this matter. That's why many manufacturers prefer to combine mineral oil with natural.

Natural Oils

This type of impregnation was used for hundreds of yearsback. With the introduction of innovative technologies, artificial petroleum products have become more popular. It took time for the person to realize the benefits of natural oil in the processing of wooden surfaces. Also, the determining factor was the high cost of the product, which was gradually solved thanks to the borrowing of modern production technologies.

The main advantages of natural oil are itsvegetable origin. The absence of harmful impurities and additives makes its use safe for human health. The most popular linen and wood oil. The latter is cheaper, but in terms of quality characteristics it loses the first.

Linseed oil for wood processing is consideredthe best Also widely used sunflower and olive oil. It should be noted that of all types of sunflower dries faster than the rest. But we should not forget that on the general background, mineral oil for wood dries many times faster, but with natural it is necessary to tinker. In order to somehow solve this problem, chemical components are added to the composition of olive, hemp or sunflower oil, accelerating the drying process.

Application features

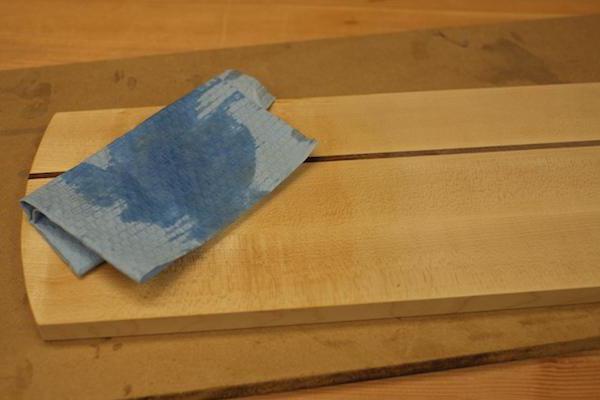

Working with oil is quite simple and does not requirespecial skills. You will need a wide brush, cloth napkins, sandpaper. The choice of a particular device depends on the method: rubbing or soaking.

- The first is the most popular.It is applicable in cases when it is necessary to cover a large surface. Wooden board with a brush is covered with oil. For the best effect, it is recommended to gradually rub the solution with napkins or sandpaper. The procedure is repeated several times, alternating the application and waiting for complete drying of each of the layers.

- The second method is more suitable for small parts. They are immersed in a special container filled with oil, and soaked for several days. After that, the part must be polished well.

Oil impregnation is quite easy to use,but indispensable for finishing work. It will help preserve the life of the wooden structure. The main thing is to take into account all the features. Mineral woodworking oil may contain toxic substances, but the drying time is minimal. A natural oil is environmentally friendly, but it will take more than one hour of drying.