Polyfoam is used in many constructionworks. It has good thermal insulation. However, this is a fragile and crumbling material. Therefore, when cutting it, special equipment is used. Otherwise, the edges will be uneven, and the material itself will lose its thermal insulation qualities at the joints.

Special equipment is on sale. but foam cutter You can do it yourself. This will significantly save the family budget. How to create different options for the tool for cutting foam, it will be interesting to know each master.

Tool type

By creating manual cutter for foam plastic, it is necessary to study the existing varietiesthis tool. There are mechanical and electrical varieties. If a piece of foam has a small size, and the accuracy of trimming is not so important, you can give preference to the first version of the tool.

However, in order to ensure a tightadherence of plates of foam plastic to each other, it is necessary to provide high accuracy of cutting. The edges should be smooth. In this case, it is possible to create a heat-insulating layer of high quality. Its heat loss will be minimal. When the cutting is uneven, large crevices form between the joints. Through them the heat from the room will go outside.

Professional designers and builders use only electrical equipment for cutting foam. At home, it is possible to create such a tool.

Simple electric cutter

Considering, how to make a cutter for styrofoam, it is necessary to study the construction of the simplestequipment of this class that operates on electricity. It will be necessary to prepare a thin guitar string and several batteries (for example, from a flashlight).

The principle of operation of this equipment is simple.The design of the batteries forms a single unit. To it connect a guitar string. When an electric current passes through the circuit, it will heat up. It is in this condition that the string can easily cut a piece of foam.

When this tool is used, the material will bemelt. The string heats up to 120 ºС and even more. In this case, it is possible to cut several large plates of foam. If you need to do a lot of work this option will not work. Quickly sit down batteries. It will be necessary to envisage the option of connecting the system to the household network.

Varieties of electric torches

Electric cutter for cutting foam can be used for different purposes. This will determine the type of construction and the overall performance of the equipment. There are three main types of self-made cutters.

The first category is used for linearcutting. The second group includes cutters, which perform the cutting of the material. They are used by designers. To perform repair of the house this variety is used less often. There is also a tool with a working plate made of metal.

Such equipment necessarily has in itsa step-down transformer. It should be designed for a minimum power of 100 watts. The secondary winding of the transformer must have a cross section of at least 1.5 mm. It must withstand a voltage of 15 V. In this case, you can achieve a high result of work.

Features of work

Studying, how to make a manual cutter for foam plastic, it is also necessary to consider the features of the operation of such equipment. As already mentioned above, such a tool has a string. It heats up and melts the surface of the foam.

Such material reacts poorly enough toheat. Therefore it is important to maintain the technology of the whole process. Cutting with a hot thread is done quickly. This allows us to achieve a high quality cut.

Проверить уровень нагрева струны просто.For this, a test is carried out on a test piece of foam. If the thread is immersed, long pieces of material remain on it, it is still not sufficiently heated. If on the string there is no foam at all, then the temperature is too high. In this case, you have to cool the tool a little. With the correct heating it is possible to perform a fast, accurate cutting.

Line Cutter

Linear DIY cutter for foam plastic will allow you to create blocks of material of the required dimensions. This greatly speeds up the work of the master. If necessary, this tool can be cut in foam plastic circles, triangles or squares.

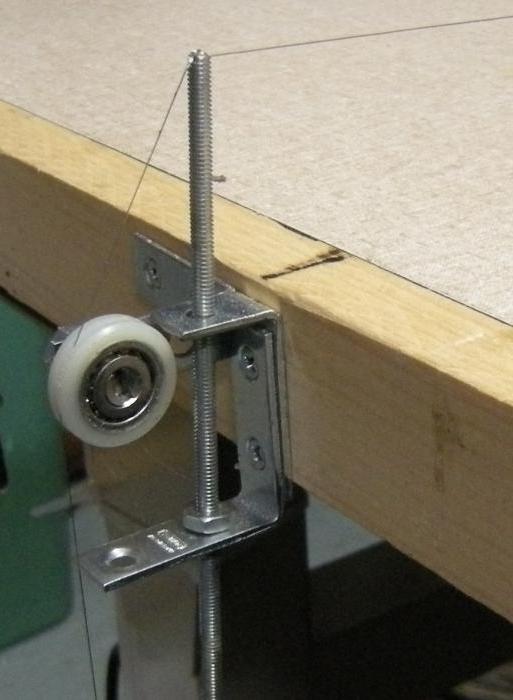

Vertically mounted on the surface of the tabletwo racks. Two insulators are attached to them. Between them stretched nichrome thread. This alloy heats up quickly, providing enough temperature for cutting. Through one of the racks pass freely hanging cargo. To the thread connect the contacts from the transformer.

Passing through the nichrome thread, the current will be herheat. It will be stretched all the time thanks to the weight hanging from one side. This is necessary because the string may sag when heated. If desired, the design can be improved by adding a spring instead of a load. However, the original version is easier to perform.

Linear cutting process

Considering, how to make a cutter for plastic foam do it yourselfIt is also necessary to understand how to work properly. Cutting can be done vertically or horizontally. To do this, pull the thread in the appropriate position.

If the string is stretched horizontally, you can make the same cuts with it. The foam is evenly pulled over the table. The thread will evenly cut it into required pieces.

When vertical cutting construction is addedframe made of metal or plywood. The holder is installed on it. An insulator and a nichrome string are connected to it. On the other side of the load is suspended. It will pass through a hole drilled in the table. It should be large enough and covered with a special insulating material. Then you can perform vertical cutting.

Figured cutting

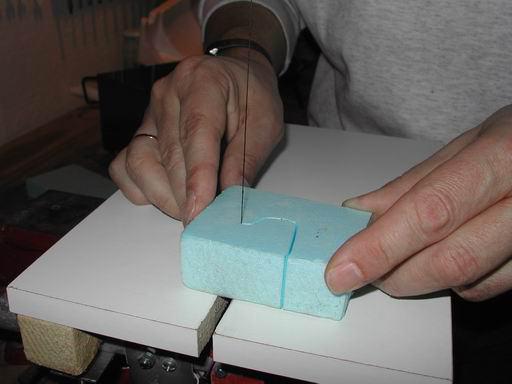

If you need to cut large enough sheetsfoam or create decorative items, sculptures made from this material, apply a special type of equipment. It can also be made independently. It's tame cutter for foam plastic. It is made on the basis of a manual jigsaw or hacksaw. In them, the cutting element is changed to a nichrome string.

Если требуется создавать фигурные элементы, можно make several tools of various shapes. Wire is supplied to the jigsaw handle. It must be carefully isolated. Otherwise, working with this equipment will not be safe. To the contacts of the wire is attached nichrome string. This can be done with the help of nuts and screws with washers.

Also to create such equipment canA pulsed soldering iron or wood burner is suitable. This tool is considered convenient. From such equipment, their work item is removed and replaced with a piece of nichrome wire. In this thread can be given a different shape.

Metal plate cutter

Exist foam cutter, in the construction of which copper is usedplate. To create this equipment, you can redo the soldering iron. Suitable equipment capacity of 60 watts. Remove the heating element from the device. Instead, set the plate here.

One side of the copper billet need to sharpen.This will allow you to create a cut of greater accuracy. Sharpening angle should not be made too large. Cutting will be done by heating. To pick up his required level, you will have to experiment on a test piece of foam.

This method is also used by masters.different skill levels and profile. If necessary, the copper plate can be replaced with a steel billet. This option will require more effort when performing sharpening. But with the help of such a tool can be cut and more dense polymeric materials.

Expert advice

Choosing which foam cutter more suitable for the wizard, shouldtake into account the recommendations of professional builders. The greater the volume of work performed, the more difficult the design will be. A simple battery cutter is quite suitable for cutting several blocks. However, to perform a large amount of work, you should give preference to the network varieties of equipment.

When cutting the foam is heated.At this moment substances that are unsafe for human health are released from it. Therefore, the work is done in a well ventilated room or on the street.

In order not to be mistaken with the cutting configuration,It should be before the action to outline all the lines in pencil. This will avoid cutting errors. These simple recommendations will allow you to perform work quickly, correctly and safely.

Having considered what options for cutting foam can be made by hand, each master will be able to choose the best option for himself.