The creation of forged products is made usinghot and cold processing. The latter method does not require special skills, but its implementation requires special tools. There are various drawings of cold forging machines, many of which are suitable for self-creating tool.

Production features

Forged metal elements are formed as a result of deformation, while in the course of work, the operational characteristics of the material should be taken into account.

Структура кристаллической решетки металла состоит from grains having an irregular shape. The tool used for forging acts on it and changes the appearance of the part. Of particular importance is the selection of machine drawings, since the workpiece must retain its former properties.

Homemade machine for cold forging: the rules of manufacture

There are certain rules, compliance with which provides the desired result:

- Creating a suitable configuration is possible with several tools.

- Before manufacturing, the parameters of the formed products are calculated.

- The rods used for blanks may have a different diameter, which is selected taking into account the degree of complexity of technology and subsequent operation.

- Only mild steel can be treated, as other species do not have the necessary ductility.

"Gnutik"

Hand tools for cold forging can be madeon your own, it’s enough to understand the intricacies of using the tool and select the appropriate drawing. "Gnutik" is necessary to create angles of various configurations. Its main structural elements are a moving stop and two shafts placed on a steel plate.

Homemade cold forging bending machinesthis type should be created in accordance with some features. For example, the angle of deformation must initially be determined. It is also possible to add an additional bending element, in case of its use the third rotating shaft is mounted.

The tool is made of special steel, as it has heavy loads in the process. It is worth noting the possibility of collecting various parts, including wavy.

"Twister" and "Snail"

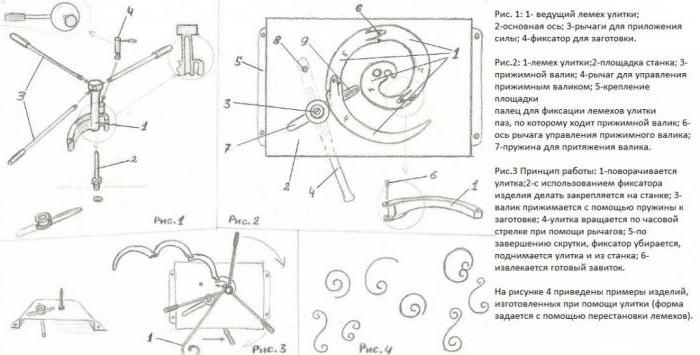

Today, art forging is not complete without screw-shaped parts. They are created by manual cold forging machines. called “Twister”.They have the characteristic feature of scrolling the rod along the axis. The tool consists of a moving and fixing part. The rotary handle deforms the workpiece, which is fixed between the main parts of the structure. It is worth noting that the spiral is formed from the side of fixing the product, and the applied efforts can be reduced by properly calculating the pressure lever. This device allows to produce parts for metal fences and window grids.

"Snail" is the simplesthomemade machine for cold forging, which provides the formation of spirals with the required number of turns. It is the most popular and can be adapted to produce the desired product. The tool is equipped with a manual or electric drive, the type of which is selected in accordance with the intensity of operation.

Homemade machine for cold forging: preparation of materials

Для начала необходимо вычертить спираль с identical step of all turns. In this case, it is necessary to make a start from the used blanks, since the stroke width is usually within 15 mm, while the tool is intended for bars with a cross section of 10 mm. Free space is necessary for maneuver, since with full compression of the workpiece bending will become impossible.

Next, you need to cut a plate size of 20x20cm from steel sheet. Despite its small size, it will ensure optimal performance of the workflow. In accordance with the length of the proposed "snail" is a cut of steel. The strip must be bent with pliers, placed on the plate and outlined with a bright marker on all sides.

Next, cut off part of the rod with a length equal tostrip width of steel. The main thing is that it does not exceed this parameter, as this can lead to injuries in the process of bending. The rod is necessary for securing the material in the first stage of product creation in order to prevent free running at one point.

Part of the profiled pipe is cut off.10 cm long. It will combine the sheet and the base on which the fixation will be made. Due to the high degree of load, only thick-walled materials should be used. After all the basic elements are prepared, you can assemble a homemade cold forging machine, the drawing of which is presented below.

Assembling the structure

The steel "snail" is divided into turns, the first ofwhich will hold the workpiece, and the others will go the turns of the rod itself. The central part is welded to the base, while on the resulting seam should be absent even the slightest flaws. The pieces of the rod are welded to the main part of the strip, the distance between them should be 3 cm. Care should be taken when forming the seams, then knock them down with a hammer.

Then installed in the required places.segments of the strip and outlined by a marker. The resulting circles are needed to form the holes. They must fully comply with the diameter of the legs to ensure easy installation and removal.

The final stage is the welding of the profilepipes in the lower part, and also the fixing element near the "snail". Photos of homemade cold forging machines made in a similar way are presented above.