The generator is a kind of power stationproviding energy to all engine systems: power, cooling, ignition, therefore, its failure will inevitably entail other problems. To prevent damage, it is necessary to systematically diagnose it, and if problems were not avoided, repair them immediately.

In this article we will talk about how to test the generator for performance, without the help of experts. But first, let's understand the symptoms of its possible malfunctions.

The main symptoms of a generator failure

The following signs suggest that the generator has failed or there are problems with its operation:

- constant burning of the signal lamp in the form of a red battery on the dashboard, which indicates that the generator does not charge, or produces an insufficient current;

- constantly discharging battery;

- interruptions in the operation of electrical equipment (lighting and signaling units, multimedia, heating and ventilation) with the engine running;

- the appearance in the cabin (engine compartment) characteristic burning smell;

- excessive heating of the generator stator;

- rumble (rustling, whistling) generator.

The appearance of such signs is a serious reasonin order to conduct a diagnosis. To do this, it is not at all necessary to contact a service station, since it is quite possible to check the generator for operation by yourself, especially if you have even the slightest skills in handling a car tester. But first, let's talk about the main breakdowns.

Major faults

The generator can have malfunctions, both mechanical and electrical. These include:

- failure of the voltage regulator;

- malfunction of the diode bridge (rectifier unit);

- short circuit of the excitation winding of the rotor;

- short circuit of the stator windings;

- brush wear;

- bearing wear.

Next, we will talk about how to test the generator for performance on its own, based on the symptoms present and possible malfunctions.

Voltage regulator check

The regulator is designed to stabilizegenerated voltage before applying to the vehicle’s on-board circuit, including the battery for charging it. Determine its health yourself can not only check the charging of the generator, or rather, the magnitude of the voltage supplied to the battery terminals. Depending on the brand and model of the machine, it can be from 13.5 to 15.5 V. Therefore, before checking the operation of the generator for the correctness of the regulator, it is necessary to know exactly what voltage it should issue. This information can be found in the car's manual.

How to check the generator with a multimeter?To do this, switch the device to the voltmeter mode and, observing the polarity, connect its probes to the battery terminals when the engine is not running. Normal is the voltage within 12-12.8 V. Next, start the motor and repeat the procedure. The voltage at the battery terminals should rise to 13.5-15.5 V. Only in this case, the regulator can be considered operational. Increasing or decreasing the voltage value, on the contrary, indicates that it is faulty.

How to check the diode bridge of the generator without removing it from the car

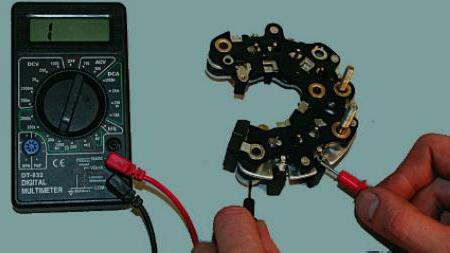

Diode bridge performs the role of a kindrectifier, converting alternating current produced by the generator, in a constant. Usually it consists of six semiconductor diodes, and three of them are “positive”, the other three are “negative”, i.e. the first pass current in one direction, the second - in the other. Testing of the rectifier can be carried out both with the generator removed and without dismantling it. Consider both options.

Перед тем как проверить диодный мост генератора, without removing it, it is necessary to disconnect from it and from the voltage regulator all the wires, having previously disconnected the ground terminal from the battery. First, let's check the rectifier for a short circuit. We turn on the multimeter in ohmmeter mode, we connect the positive (red) probe to the output “30” of the generator (positive contact of the bridge), and the negative one to the generator body. If the rectifier is in good condition, the instrument readings will tend to infinity. If the resistance is several ohms, the rectifier is faulty.

Теперь поговорим о том, как проверить диодный bridge generator for the presence of breakdown. Let's start with positive diodes. Again we connect the positive probe to the corresponding bridge contact (pin "30"), and the negative one to the bolts (brackets) of the rectifier fastening. The resistance should also tend to infinity. Otherwise, one or more diodes are punched.

We turn to the "negative" semiconductors.The red probe of the tester is attached to the bolts of the rectifier, black - to the generator body. Resistance tending to infinity is a sure sign that the diodes are intact.

Check the rotor winding

Frequent malfunction car generatoris the closure of the windings. This can happen as a result of an abrupt voltage surge, water ingress, brush wear, etc. Since you can check the generator with a multimeter for the integrity of its windings, you can only dismantle the entire assembly if you get full access to them. We will not describe this process, since it is different for different cars. Before checking the removed generator for operability of the rotor winding, it is naturally necessary to disassemble it.

После извлечения ротора находим на его валу slip rings. There are only two of them. Turning on the multimeter in ohmmeter mode, connect its probes to these rings. The device must produce a resistance in the range of 2-5 ohms. These are normal values for a serviceable rotor. Higher resistance indicates poor contact between the rings. In the opposite case, when the instrument readings approach zero, the interturn closure is likely to occur.

How to check the generator for operation of the stator windings

Go to the stator. It has several windings, each of which must be checked separately. But before that, it is necessary to disconnect the wires connecting the terminals of the windings and the diode bridge.

Test leads of a multimeter switched on in ohmmeter mode are alternately connected to the terminals of each winding. For a working winding, the resistance should be about 0.2 ohms.

Next, you need to measure the resistance between the common output (zero) of the stator and the output of any of the windings. It must be at least 0.3 ohms.

Worn generator brushes

If the generator has already been dismantled and disassembled, notinterfere with checking the condition of the brushes. They can fail due to long-term operation, or as a result of problems caused by rotor shaft skewing. If the brushes have traces of large wear, their geometric shape is broken, they must be replaced.

Worn generator bearings

Automotive alternator has two bearings.One of them is mounted on the rotor shaft, the second is pressed in the central part of the cover. A buzz, a whistle coming from the generator while the engine is running is a sure sign that one of the bearings ordered to live long. A concomitant symptom may be the heating of the generator case. Having found these signs, hurry to replace the bearings. Otherwise, it will cause a distortion of the rotor shaft or its jamming with all the ensuing consequences.

Проверить подшипники можно, сняв ремень generator and cranking his shaft. If the rotor rotates easily, without jerks and play, the bearings still serve. If the rotation is difficult, or the shaft has a backlash, do not pull with the replacement of bearings.