When settling the centralized and autonomous sewage system, a well is mandatory. It allows you to periodically maintain and clean the construction of waste water disposal. Polymer well today is in demand among consumers. This is due to its characteristics and reasonable cost.

Plastic wells allow cleaningformed clog, to check the efficiency of the sewage system. You can install such an element of the system yourself. What to look for when selecting, and also how the installation is done, should be considered before starting work.

Appointment

Polymer well It is a device that allowscontrol and provides access to sewage pipes. In addition, there are a variety of designs in which you can store an electrical cable. Wells are used in stormwater, drainage, fiber-optic, gas, sewer, telephone and other networks.

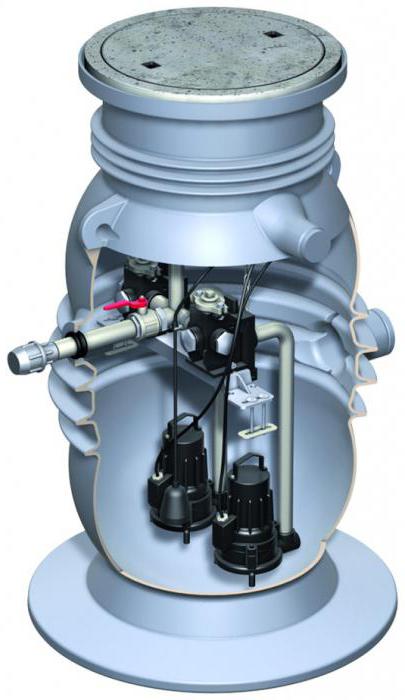

To perform its functions, the product has a bottom,mine (body), throat and hatch. Also in its structure can include bends and branch pipes, leading communications. Previously, brick wells were used. In their place came new materials. Reinforced concrete species require special installation costs. Therefore, many owners of private homes prefer polymer options.

According to building codes and regulations, such products must be installed in all sewerage networks. It must be installed in the places of rotation or change in the level of the pipes.

Design

Each well has the basic elementsstructure. The first of these is the bottom. It allows you to hermetically close the internal space from the ingress of groundwater or liquid from the well to the ground. This element must withstand heavy loads.

Hatchways for manholes, polymeric have standard sizes.They are laid on the neck, if the cover refers to a variety of pedestrian or technological. If the hatch is automobile, it is mounted on a special base plate. This prevents the punching of asphalt near the well.

Pipes connect the system with various communications. They can be created for PVC exits, corrugated tube. The designation of the diameters of the cross-sections can be made on the inner or outer part.

Types of wells

Presented elements of the waste management systemcan have different dimensions. This characteristic is determined by the daily disposal of sewerage. Depending on the purpose, there are inspection, water intake and polymer-sandy well.

Also distinguish domestic, drainage, industrial and storm wells. They can be made of polyethylene, PVC, polypropylene, a mixture of various polymers.

By the technology of manufacture, there are welded andsolid designs. If you want to install a large enough well, it can be assembled from several parts. But for a small shaft the whole type of construction is suitable.

The difference between the wells is also in the internal space. There are products with smooth walls, as well as corrugated varieties. In the latter variant one and two-layer walls are distinguished.

Cost

Modern polymeric wells, price which can be significantly different, cancharacterized by different qualities. According to buyers, such structures should be strong enough, resistant to groundwater pressure and other loads.

That the products represented correspondsanitary and building requirements, most often in the creation of their design, ribs are provided. Such wells cost around 15-25 thousand rubles. Such structures are able to withstand various adverse environmental influences, to last a long time.

The sales also include smooth-walledstructure. They do not have high strength. Their cost can be in the range of 6-10 thousand rubles. According to users, these products are not able to withstand even one year of operation under the condition of a snowy winter.

Hatchways for manholes, polymeric sold separately. Their cost can vary from 1 to 5 thousand rubles. When choosing, it is necessary to take into account the operating conditions, the size of the loads that will affect the system.

Hatch strength class

Polymer well can have different dimensions, strengthand the number of composite elements. The final cost of the construction depends on this. When choosing, you should also pay attention to the hatch class. This is one of the most important components of the system. There are 4 classes of covers for wells.

The standard "D400" is intended for automotivehighways. It is capable of withstanding the maximum loads. For the arrangement of sewerage in the city, where the hatch goes to the roadway, the product "C250" is suitable. It can withstand loads of up to 25 tons.

For sidewalks, park areas the hatch is quite suitableclass "B125". It is also used in parking lots. For a private house it will be sufficient to purchase a "A15" hatch, if it will go out on a green lawn or pedestrian walkway. In this case, the cost will be much lower.

Advantages of plastic

Sewer Polymer Wells have several main advantages.The presented constructions are characterized by high strength. If necessary, they can be further strengthened. The tray part is resistant to wear, which allows to significantly extend the service life.

The inlet and outlet pipes are connected to the well in a sealed manner. Factory connections also have a high level of tightness. When constructing a structure, you can specify any dimensions of the product.

Installation of plastic wells is easy andfast. The cost of their acquisition and installation will be minimal. Plastic is resistant to corrosive effects of effluents. The presented products are practical, at an affordable price. This makes them today in demand.

Features of choice

To properly operate the sewage system, you need to pay attention to the correct choice of the product variety. it happens polymer-sand well, inspection and water intake structures.

In the first variant, the article has a length of 2 m, andthe width of the mine is 1.5 m. On its bottom there is no throwing. Here, drainage material (gravel, gravel) is poured, which lets the treated drains into the ground. Thanks to a special design, such structures catch sand and other small particles, not passing them into the soil.

Sightwells are needed for potentiallydangerous sections of the water supply. In such places, communication is changing its direction. In the event of a breakthrough, the master will be able to reach the pipe and fix the problem.

The storage facilities keep inside themselvesDrains before they are pumped out. This option is used in an area where there is no centralized sewage system. In order not to send drains to the ground, a similar system is used.

Prefabricated and monolithic structures

The buyer has the opportunity to choose prefabricated or monolithic structures. In the first case, they are purchased polymer rings for the well. They are assembled on site.With the help of such elements it is possible to assemble a structure of almost any depth. Each component has a sealing ring. Their quality depends on the tightness of the well. The more parts used to create a design, the more flexible it will be. But this increases the likelihood of leakage.

If it is required to provide increased strength of the walls of the well for compression, monolithic structures should be purchased. It is important to correctly estimate the volume of water that will be inside.

Materials

Sewerage in a private house with their own hands, scheme which is developed taking into account the features of operation, can be created from various materials.

PVC systems are highly resistant toaggressive substances, as well as incombustibility. However, in conditions of temperature changes and the need to ensure a high level of tightness, it is better to give preference to wells made of polyethylene. They are able to withstand soil pressure even in severe frosts.

If the probability of impact on the walls is highit is recommended to install structures made of polypropylene. It is a plastic, durable material, resistant to wear. It can also be soldered. Therefore prefabricated structures are preferable to create from polypropylene.

Features of the installation

Sewerage in a private house with their own hands, scheme which does not differ much complexity, is mounted in several stages. This does not require the use of additional special equipment. Installation does not take much time.

First you need to dig a pit.It should be 20 cm wider than the well. The bottom is lined with gravel. If it is intended to create a cumulative structure, the foundation is concretely concreted For drainage varieties, cement is poured only around the perimeter.

Well with special equipmententer into the pit and fix the cables. Next, connect the sewer pipe. The tank is filled with water and backfilling is made. The technological ring, a cover of the hatch is established.

After appropriate testing for tightness of all elements of the system, the sewer well can be operated for its intended purpose.

Having considered what constitutes polymer well, as well as its features and varieties, eachthe owner of a private house will be able to choose the best option. Do-it-yourself installation, performed in accordance with the recommendations of building codes, will be carried out quickly and efficiently.