One of the standard connection schemes withUsing a reversing starter allows you to change the direction of movement of the shaft. In addition, the starter's purpose is to start, stop, and protect the three-phase asynchronous current motor.

Basic principles of work

The basis of the reversing starter iselectromagnetic three-pole contactor of alternating current. This part is considered to be the most important, and it also provides all the functions that relate to working with the rated current and voltage, as well as the switching capabilities of the starter and its resistance to mechanical wear.

The reversing starter can operate in several modes:

- The first working regime was called "long-lasting";

- The second mode of operation is intermittent-continuous;

- the third mode - repeatedly-short-term;

- The last operating mode of the starter is short-term.

In order to know the duration of switching on of each individual model of the reversing starter, it is necessary to refer to its technical specification, which is attached to each product.

Starter connection

Connecting this switchgearis carried out in the same way as all the others, with the exception of the reverse button, as well as the magnetic starter. For these reasons, the connection circuit of the starter of this type is not too different from the usual, standard version.

Первое, что необходимо обеспечить в схеме, - это full performance of the reverse engine, which should be implemented by changing the location of the two phases. At the same time, it is necessary to ensure the operation of a mechanical locking system that will not allow the second starter to automatically turn on or off. If we allow the simultaneous activation of two starters at once, this will cause a short circuit.

Starter circuit operation

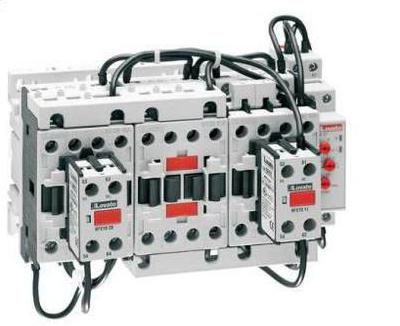

The scheme of the reverse actuator with mechanicalinterlocking includes two identical starters. When the circuit is turned on, one of them starts the electric motor of the engine in one direction, and the other in the other. If we consider the essence of the connection, then the scheme is quite similar to the connection of two single starters, but there is still a difference. It consists in the presence of one common button “Stop”, as well as two buttons “Forward” and “Back”. In the same case, an electric or mechanical interlock is used, which is designed to protect the device from a short circuit in the event that two starters turn on simultaneously.

The occurrence of a short circuit

Для того чтобы сменить направление вращения Asynchronous motor, you need to swap two phases. In other words, if they are in the “ABC” order, then they should be on the second, for example, on the “ABA-B”. It is this phase change process that the reversing starter monitors. This suggests that simultaneously turning off both models will result in a short circuit in the circuit. In order to avoid this, there are constantly closed contacts in the network, which, when the starter is switched on, create a break in the control circuit of the second starter, and at the same time an electrical interlock occurs. However, there is also a mechanical type of lock. The essence of this process is quite simple. At the moment when the second starter is connected to the network, the mechanical device turns off the first one.

Circuit assembly

In fact, to collect such a scheme is quitesimple, and most people can do it themselves. The reversing starters are located in the housing, all that is required for connection is the correct connection of the contacts. However, it is important to say here that mechanical blocking does not lend itself to independent production, here it is necessary to buy a factory product.

It is recommended to start from the power part of the circuit.On the machine is fed three different phases, which are most often indicated as follows: yellow "A", green "B" and red "C". After that, they are fed to the power contacts of reversing starters, which are usually referred to in the schemes as KM1 and KM2. On the other side of these phases, three jumpers are created between the central green phases.

After assembling this part of the wire is connected tomotor through thermal relay. It is important to note here that the current will be monitored only in two phases. To monitor the current in the third phase does not make sense, since all of them are rather closely interconnected. In other words, if you increase the current in one phase, then the same will happen in the remaining two. This suggests that raising this parameter to a critical level will cause both starter coils to turn off immediately.

Mechanical interlocking reversing starters PML

The use of this type of reversing starters is also carried out where it is necessary to monitor the start, reverse and stop of an asynchronous three-phase motor.

The design of these devices is considered quiteplain. The body is made of plastic, and inside there is an anchor and a core. A special pull-out coil is mounted on the core. Due to the peculiarities of the scheme of this device, it turns out that the entire upper part of the body is occupied by traverse guides, over which an anchor is mounted. In addition, special bridges with springs, which are designed to block the product, are also mounted near this element.

The principle of operation of this device is quite simple.When current is applied to the device, the voltage accumulates in the coil, because of which the armature begins to attract itself. When these two parts close, the armature opens the closed contact and closes the open. The switching off of the PML reversing starter occurs at the moment when the contacts open.

Starters "Schneider"

Quite a common technique in the market of electrical appliances. This company has a series of EasyPact TVS. The advantages of the Schneider reverse starters in this series are as follows:

- rated current is in the range from 9 to 150 A;

- rated voltage reaches 690 V;

- a fairly wide range of operating temperatures from -50 to +60 degrees Celsius;

- there are built-in additional contacts of instant type;

- number of poles - 3 or 4;

- One of the most important advantages is a rather wide control voltage range.

The design and operation of the reversing magnetic starter

Распространение этих моделей становится все шире every year, as they provide an exceptional opportunity to control an asynchronous motor from a distance. This device allows you to turn the engine on and off. In the case of the reversing starter there are 4 components:

- Contactor.

- Thermal relay.

- Casing

- Management tools.

After the start command arrives,electrical circuit is closed. After this, the current begins to flow to the coil. At the same time, a mechanical locking device is activated, which prevents unnecessary contacts from starting. It is worth saying that the mechanical lock also closes the contacts of the button, which allows you not to keep it pressed all the time, but calmly release. Another important detail is that the second button of this device, along with the launch of the entire device, will open the circuit. Because of this, it turns out that even pressing it does not give any result, creating additional security.