Quite common in recent times withlandscaping rubber tiles, do it yourself can be made, which will save. As a result, it will be possible to get products that have a bright appearance and are characterized by ease of installation.

Features of rubber tiles

Although the rubber tile appeared onThe Russian building materials market is relatively recent, it has managed to gain a decent position, because the products have excellent qualities, among them anti-slip features that allow you to use tiles at any time of the year. If a crust of ice forms on the surface of the coating, then it can be easily removed by using the crowbar.

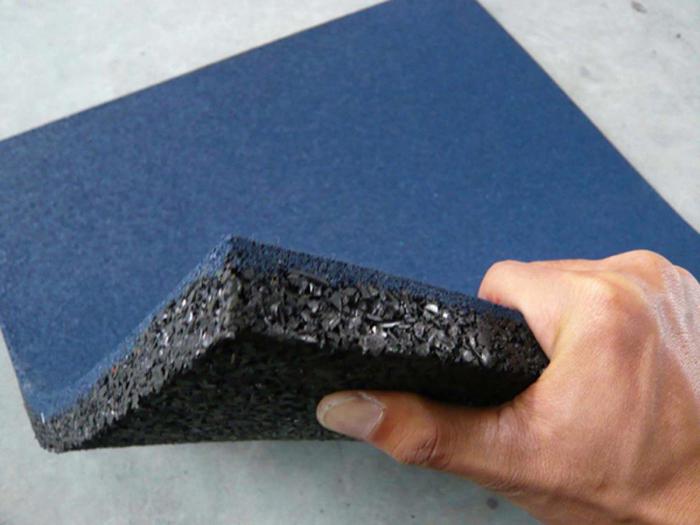

The rubber paving slabs from a crumb havelong term life, the material is quite durable, not erased with impressive mechanical stress. You will not face the problem of puddles on the surface of the tracks of this tile, as it has a drainage effect due to its porous structure. Products pass moisture well. After the products are ready, they can be laid on any type of base, it can be, for example, gravel, soil, concrete, sand, as well as asphalt.

Raw materials for making tiles

Rubber tile do it yourself withusing crumb rubber, which acts as a product of recycling tires. The starting material is rubber, which can be natural or artificial. This causes the quality of the strength of the final coating, as well as its extremely high resistance to mechanical wear. Thus, the production of the described products allows you to perform two functions, one of which is to manufacture a material with excellent performance characteristics, while the second is expressed in the safe disposal of unwanted goods.

Technical equipment

Rubber tile do it yourselfMade only with the appropriate equipment, which has a very impressive cost. If you intend to engage in manufacturing for business, then its acquisition is advisable, whereas if you are faced with the task of laying a path on the garden, it is preferable to purchase products in finished form, it will be cheaper even if the installation is rented.

For the production of rubber tiles should be bought:

- heat chamber;

- mixer;

- conductor for holes;

- Hydraulic Press;

- set of forms;

- platform, tables and stands for the mixer.

If you are planning to purchase such equipment,then you will have to pay approximately 1,590,000-2,370,000 rubles. In the minimum price option, you will receive the most modest set of equipment, while the highest price includes a mini-factory.

Technological process of production

DIY Rubber Tile Productioncarried out by the method of initial removal of steel elements from tires. After the prepared rubber products are subjected to grinding to particle sizes ranging from 1 to 4 mm. Then the baby combines with a binder polyurethane mixture, pigment and brought to a uniform state. The mixture must be poured into molds, subjecting future products to vulcanizing oppression.

Making a rubber tile with your own hands canproduced by the method of hot or cold pressing, but both of these processes are carried out when exposed to elevated temperatures. In the first case, the temperature is maintained within 140 ° C for a quarter of an hour, while during cold processing the products undergo a four-hour treatment at 80 ° C. If we consider the final qualitative characteristics of the finished product, then both of the listed methods are equivalent, in the matter of energy consumption, the methods are also equivalent. But if you set up a production line on your own, the “hot” method will be much cheaper, but if you want to increase productivity, then you should choose the “cold” technology to readiness.

Production features

Если в основе вашего бизнеса будет резиновая tile, it will turn out to be produced by own hands, having invested approximately 2 million rubles. This includes start-up and equipment costs. Any novice businessman is interested in the question of when the matter starts to pay off. In the described case, this will happen in about 6 months. Rubber tiles can be delivered to stores, from there they will be purchased for furnishing children's and sports grounds, private garages, backyard paths, gazebos, and terraces.

Myth of the production of rubber tiles

Несмотря на то, что в магазинах представлена по affordable prices rubber tiles, do it yourself house craftsmen continue to produce. But still there are myths about quality or the production process. One of them is expressed in the fact that the products produced by the hot pressing method are of not so high quality as compared with the analogues obtained by the cold process technology. This statement absolutely can not be considered correct. It is today refuted by manufacturing companies using both methods.

Styling

Laying rubber tiles do it yourselfwith the arrangement of lighthouses. After the territory is prepared. Initially crushed stone is laid on the ground, it will act as a drainage layer. Be sure that the installation should be done on the basis of a certain slope, this will allow wastewater to drain to the sewer. A curb should be placed along the edges of the path, otherwise the sidewalk will crawl at the very first snow melt. Before proceeding to the installation of tiles, should lay a sandy layer. For which it is recommended to use only pure sand, which has no additional impurities. The thickness of this layer should be about 5 cm.

Laying products should be carried out in advancestretched cord, which is located around the perimeter of the marked area, you can stretch it by pre-installed pegs. After every 3 stacked rows, it is necessary to carefully analyze the flatness of the location of each tile separately. You can allow some error, which is limited to the limits of 0.5-1 cm. As soon as one element was in its place, its position can be corrected by soft tapping with a rubber hammer. If the space reserved for the track is left free around the edges, it can be filled with plate elements, which are recommended to be cut using diamond chips.

Final installation work

Having completed laying the tile, its surface is to becompact, applying a vibrating plate and covered with clean sand, after which it will have to be swept away, which will allow to hammer in the seams. Tile made of crumb rubber, can be used to refine the backyard plot. Rubber paving slabs with their own hands can be made in short terms, and then it will fit into any exterior and will last for quite a long period of time.