Modification of the screwdriver to lithium batterieshas the meaning. The advantage is that they have a high electrical density. As a result, by installing such a device in the screwdriver body, we will be able to achieve an increase in the tool operation time many times. Charging current for high power lithium batteries, especially for new versions, it can reach 1-2 C. This device can be recharged in 1 hour without overstating the parameters recommended by the manufacturer and without spoiling the product quality.

What do lithium batteries look like?

Most lithium devices are enclosed inprismatic case, but some models have a cylindrical shape. In such batteries, rolled electrodes and separators are used. The body is made of aluminum or steel. The positive pole goes to the cabinet cover.

In prismatic configurations, the electrodes havekind of rectangular plates. To ensure safety, a battery is provided with a device that acts as a regulator of all processes and opens an electrical circuit in critical situations. Increased sealing of the housing does not allow the electrolyte to flow out and to penetrate into the oxygen and moisture.

What measures should be followed to avoid damaging the lithium battery?

- Due to technology limitationsThe charge of lithium batteries should not be higher than 4.25-4.35 V. The discharge should not reach the indicator of 2.5-2.7. This condition is indicated in the technical passport for each specific model. If you overestimate these values, you can disable the device. Special charge and discharge controllers are used, which keep the voltage on the lithium cell within the normal range. Modifying the screwdriver to a lithium battery with a controller will protect the device from malfunction.

- Lithium battery voltage indicatora multiple of 3.7 V (3.6 V). In Ni-Mh-models, this figure is 1.2 V. This phenomenon is explainable. The nominal voltage in lithium devices is stored in a separate cell. A 12 volt lithium battery will never be assembled. The rating will be 11.1 V (three consecutive cells) or 14.8 V (four consecutive cells). In addition, the lithium cell voltage indicator changes when operated with a full charge of 4.25 V, and when fully discharged it changes by 2.5 V. The 3S voltage indicator (3 serial - three serial connections) will change when the device functions from 12.6 B (4.2x3) to 7.5 V (2.5x3). For the 4S-configuration, this figure ranges from 16.8 to 10 V.

- Modification of the screwdriver to lithium batteries18650 (the vast majority of products have exactly this size) requires taking into account the difference in size with Ni-Mh-cells. The diameter of the cell 18,650 is 18 mm, and the height is 65 mm. It is very important to calculate how many cells fit in the case. It should be remembered that for a model with a capacity of 11.1 V, you will need a number of cells that are a multiple of three. For the model with a power of 14.8 V - four. Another must fit the controller and switching wires.

- A lithium-based battery charger differs from a Ni-Mh modification device.

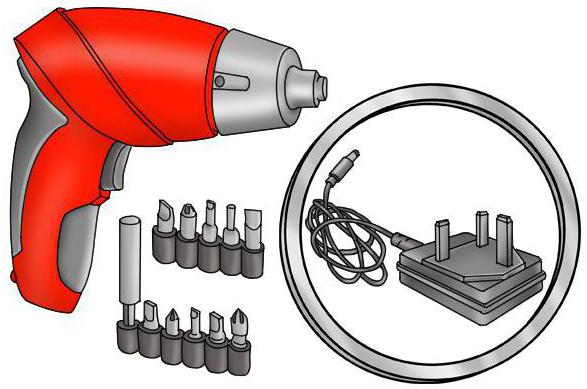

В статье будет рассмотрено, как происходит rework screwdriver on lithium batteries Li-Po. The instrument is equipped with a pair of Ni-Mh-rechargeable batteries with a voltage of 12 V and a capacity of 2.6 Ah. Consideration of a Hitachi screwdriver. Lithium batteries provide long-term service to the device.

Choose the rated voltage

First of all, you should decide on the choicevoltage rating for a device based on lithium. The choice should be made between the 3S-model (its voltage range is from 12.6 to 7.5 V) and 4S-Li-Ion-battery (voltage range is from 16.8 to 10 V).

Advantages of the second option

The second option is more appropriate becausethat the voltage in the battery quickly drops from the maximum to the minimum (from 16.8 to 14.8 V). For an electric motor, which, strictly speaking, is a screwdriver, an excess of 2.8 V is not a critical mark.

The lowest voltage3S-Li-Ion-modification. It is equal to 7.5 V, which is insufficient for the normal functioning of the electrical device. Mounting four configurations, we will increase the battery's electrical capacity.

How to decide on the choice of lithium cells?

To make lithium-based cell selection, you should outline the limiting factors. Currently, lithium devices are being manufactured with a permissible current load of 20-25 A.

Pulsed current values (short, up to 1-2 seconds) reach 30-35 A. The configuration of the battery will not be disturbed.

How many cells fit in the case?

Assemble 4S2P (four consecutive connectionsand two parallel) will not work. Alteration of the screwdriver for lithium batteries 18650 assumes the presence of eight cells. How can they meet four? Each cell will lay the maximum load current.

How to determine the maximum current in the screwdriver?

Alteration of 12V screwdriver to lithiumBatteries involves connecting the device to a laboratory power source with a maximum current of 30 A. The limiter regulator is set to the maximum value. Having created the voltage level of the power source close to the nominal indicator of the future battery, we begin a smooth pull on the trigger. The current consumed by the screwdriver rises to the level of 5 A. Now you should sharply pull the trigger. This will short the power circuit. The current will reach a power of 20-30 A. Perhaps its rate would be much higher, but the power of the power source will not allow it to fix. This will be a short load current with a sharp pull on the screwdriver trigger. Any model of such a device will react in the same way.

Далее следует зажать наконечник шуруповерта with a vice and observe to what value the current consumption will increase during the operation mode, when the ratchet will work in the screwdriver. The current index in this case increases to 10-12 A.

So you can determine the magnitude of the load current.In this case, it will be equal to 5 A at idle and 30 A at an abrupt start, and at maximum load it will be 12 A. The manufacturer should choose lithium cells, the nominal load current of which will be 10-20 A, and pulsed - 25-30 A.

How to choose a controller?

So, there is a remake of the screwdriver for lithium batteries. Regular charging for the device is required. When choosing a controller, note that the device must meet two parameters:

- rated operating voltage;

- the rated operating current.

With voltage everything is very clear: if the battery is 11.1 V, then the controller will be with the same voltage.

The term "rated operating current" impliesbandwidth protection board. Thus, the 4 A controller is designed for a current of 4 A, and at 8 A, an additional load rests on it. In this case, the protection device will work. All these technical data are set out in the passport of each modification of the controller. In this case, one modification may have a current limit of 30 A, and the other - 50 A. And both of these devices will formally be suitable for operation. Also, when creating a lithium battery has a limit in size. Therefore, you should purchase a controller that fits in the case of an old battery.

Disassembly and assembly

Conversion of the screwdriver to lithium batteries includes the following steps:

- Open the old battery by unscrewing the five screws.

- Remove the Ni-Mh battery from the case.It will be noticeable that the contact pad, which engages with the contact group of the screwdriver, is welded to the negative contact of one of the Ni-Mh-cells. Welding points should be cut with a tool with a DREMEL 4000 cut-off stone mounted into it.

- Wires are soldered to the contacts, the cross section of which is not less than 2 mm2 for power leads and 0.2 mm2 for thermistor. The contact pad is glued into the battery case with hot melt glue.

- According to the indicator of internal resistance, four cells are selected on the meter. The value must be the same for all four instruments.

- Lithium cells are glued with hot melt so that they are located compactly in the case.

- Welding of cells is carried out on the machine for contact welding by means of welding tape from nickel (its cross-section indicator must be equal to 2X10 mm).

Installing a security card

This stage can show how much easierlithium battery design. The weight of the device Ni-Mh was equal to 536 g. The weight of the new device from lithium is equal to 199 g, which will be quite noticeable. In weight managed to win 337 g. At the same time an increase in energy capacity is observed.

The battery is mounted in the case. The voids are filled with soft material from the packaging.

Connect to the screwdriver

- A sharp push on the trigger triggersprotective mechanism for current. But in fact, such a protective mode is unlikely to be needed when using the tool. If you do not specifically provoke protection, then the work of the screwdriver will be different stability.

- The tip should be clamped in a vice. The power of the battery freely triggers the ratchet, which limits the increase in the number of revolutions of the torsion.

- Lithium battery screwdriver discharges at electronic load. The discharge current indicator should be 5 A.

- The battery is inserted into the standard memory.The charge current in measurement is 3 A, which is valid for lithium cells. For the configuration of the LG INR18650HG2, the maximum charge current will be 4 A, which is indicated in the technical specification.

How long does it take to replace batteries?

The conversion of the screwdriver to lithium batteries takes about 2 hours. If all the parameters are checked, then it will take 4 hours.

Everything can be done independently, without the help of another person. But contact welding and the choice of batteries without specialized equipment does not hold.

How can you still test the charge level other than the controller?

Lithium screwdriver reworkedbatteries. Native charging built into the case is ideal. But the cost of the controller is quite high. The device will cost $ 30, which is equivalent to the cost of the battery itself.

To test the charge levelLithium battery on the go, without using a charger, you can use the special indicator RC helicopter lipo battery AKKU portable voltage meter tester alarm 2-6S AOK. The cost of the device is very low. It has a balancing and charging connector similar to the iMax6 device. The device is connected to the battery by means of an adapter. This device for monitoring the voltage level is very convenient. It can measure from two to six cells of lithium connected in series, and also give a total indicator or voltage of each element separately with maximum accuracy.

How much will it cost to replace a Ni-Mh with a lithium device?

What cash costs will require reworking a screwdriver for a lithium battery?

The price of such a device consists of the cost of several components:

- 4S-lithium battery configuration costs 2200 r .;

- buying a controller for charging and discharging plus a balancer costs 1240 p .;

- The cost of welding and assembly is 800 p.

It turns out that the lithium battery, made by hand, takes about 4240 p.

For comparison, take a similar configuration fromlithium factory production. For example, the device Makita 194065-3 is designed for the screwdriver. It has similar parameters. The cost of such a device is 6500 p. It turns out that reworking a screwdriver for lithium batteries saves 2300 r.