Чтобы обеспечить работоспособность водопровода, little to organize a well or well. It is also necessary to take care of the delivery of water to the house. If the well is at a distance from the structure, and its depth exceeds 10 m, it is advisable to use a horizontal centrifugal pump. Units of this category are able to supply water under pressure to a height of more than 80 m, while spending the minimum amount of energy.

Principle of operation

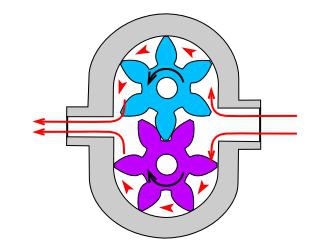

The horizontal centrifugal pump creates sufficient head due to the centrifugal force that arises from the rotation of the internal wheel of the unit when exposed to liquid.

By means of a suction pipe, water fillsThe pump body, the inner part of which has a similar spiral. Here are the impellers in the form of blade blades. When the latter is activated, the water is thrown to the walls of the hull by the action of centrifugal force. The larger the diameter of the impeller, the higher the pressure of the discharging water.

Design

The horizontal centrifugal pump contains the following main components. It:

- Housing.

- Receiving valve, protected by a grid, which serves to screen out impurities.

- Impellers with blades.

- A safety valve that protects the horizontal centrifugal pump against hydraulic shocks.

- The manometer.

- Automatic catch.

Classification

Currently, a wide range of individual modifications of aggregates are allocated depending on the design. Let's consider the options that are most in demand in everyday life and in production.

Single-stage

Centrifugal horizontal single-stage pumpdue to its name, the nature of the connection of the impeller with the shaft. Here, the shaft functions as a console in the space between the front bearing and the wheel. The mechanism is located on a foundation plate, where it connects to an electric motor.

Centrifugal horizontal pump is intendedSingle-stage for working with clean liquids. This, in turn, means that the units of this category should be used for pumping a chemically inactive medium with low density indices.

Multistage

Multistage centrifugal pumpsHorizontal contain several impellers on the common shaft. The principle of operation of equipment of this category can be compared with the operation of several single-stage units with a serial connection. The main task of such systems is the formation of an impressive head with relatively low fluid flows.

Cantilever

From the point of view of hydraulics, such an aggregateis a mechanism with a centrifugal wheel in the form of two disks, between which are the blades. The latter have a bend opposite the direction of rotation of the wheel.

Centrifugal horizontal cantilever pumpIt is characterized by high efficiency of operation, which is ensured by an impressive speed of the working blades of the mechanism. When the wheels rotate, the centrifugal force creates a vacuum effect in the pressure line, resulting in increased pressure in the peripheral zones.

Centrifugal horizontal cantilever pumpIt is widely used in the organization of water supply, heating and heat supply systems. Often, the use of such equipment is resorted to when it is necessary to meet domestic needs, for example, when watering personal plots, when a conventional single-stage pump is not sufficient due to the low water pressure.

Chemical

Centrifugal horizontal chemical pumpsare produced mainly in a multistage version. They are industrial units that are used to move neutral, toxic, chemically aggressive, flammable and harmful liquid substances. Often used for pumping liquefied gases, evaporation of which in combination with air form explosive mixtures.

Cryogenic

Horizontal centrifugal pump cryogenichas a similar principle of action, characteristic of aggregates of the previous classes. A decisive difference is the possibility of installation on vehicles in the form of an element of complex technological systems for the preservation of cryogenic products.

Dimensions

Choosing horizontal centrifugal pumps forwater, special attention should be paid to their size. Typically, the diameter of the unit has no determining value. But the length significantly affects the safety of subsequent operation in specific conditions.

If the well differs by a depth of about 10 m, andthe water level is at a distance of 3 m from the top, here you can install any pumps longer than 90 cm. After all, from below, and from above equipment will be a sufficient layer of liquid.

With a lack of water in the well, use "long"units are prohibited. In such cases it is worth giving preference to submersible centrifugal models. The latter are less sensitive to solid particles and sand impurities, protected from "dry running" due to float switches.

Performance

Selection of a centrifugal pump in accordance withThis parameter depends entirely on the water flow in the water supply system. The capacity of the unit should somewhat exceed the needs of the tenants in the water. Determine the required value allows the summation of the fluid flow by all "consumers", in other words - washbasins, showers, sinks, washing machines, other plumbing fixtures.

Benefits

Advantages of centrifugal pumps can be conditionally divided into functional and constructive ones.

Такие агрегаты чрезвычайно компактны за счет motor and steam turbine connections. As a result, the units themselves have small dimensions, low weight, despite their impressive performance. To install a centrifugal pump requires a minimum of free space and a relatively light foundation.

Among the functional benefits worth notingsimple adjustment and quick activation. Centrifugal pumps continuously and extremely smoothly deliver working fluids. In this case, the likelihood of hydraulic shocks in the pressure wire is significantly reduced.

Such equipment is suitable for pumping substances with a high content of pollution, suspended matter and particulate matter.

The budget cost of most models is a consequence of the use of inexpensive bases such as steel, polymeric compounds and cast iron as materials for the manufacture of materials.

Applications

Centrifugal pumps suitable for pumping waterany hardness, temperature, viscosity. As a result, their operation is not limited to the domestic sphere. Often, such units are used by enterprises of the oil industry, utilities organizations, mining companies.

Submersible pumps are used forpumping clean water from wells and wells, draining flooded rooms. Preferring such equipment for the implementation of these needs, consumers are guided by the possibility of continuous operation of the units for a long time.

Centrifugal pumps are widely used as an element of petrochemical installations, equipment for the production of food, means for chemical processing of substances.

Features of operation

To extend the service life of the pump and ensure its trouble-free operation, it is necessary to complete the unit with a certain set of additional elements.

To protect the impellers from penetratingthe system of foreign bodies input lines of the units are closed by filters and valves. In order to avoid the outflow of the pumped liquid in the opposite direction, gauges are installed to control the level of pressure and special shut-off valves.

When selecting the dimensions of the pump, they are based on the value of the necessary key characteristics: head, performance, which the unit must provide, taking into account the resistance of the plumbing system.

Horizontal installation of a submersible centrifugal pump in the well

Centrifugal submersible unit is placed in the well with a cable. As an attachment, a special metal frame is prepared, which is fixed above the tank.

Installation of the pump is carried out in strict sequence:

- The unit fits into the end of the pipe section, through which it will be connected to the tee extending into the pipeline.

- A cable is prepared for connecting the equipment to the network.

- A brass or plastic coupling is connected to the pump's check valve, which, in turn, fits in with the pipe.

- After combining the safety cable, pipe and electrical cable into a single design, the pump slowly falls into the well.

- When the submersible unit is at the required depth, the cable is fixed on the previously prepared metal frame.

- The vertical pipeline connects to the tee inside the well.

- An electrical cable is led outside and, if necessary, it runs into a trench leading into the house.

Upon completion of the above activities you canfocus on laying the pipeline in the foundation of the structure and its connection to the location of the equipment, whether it is a boiler, a hydraulic accumulator, or a water filter.

Eventually

Centrifugal pumps are among the most numerous.a group of equipment intended for pumping liquid substances. As can be seen, the units of this category differ somewhat in their areas of application and functional purpose. Household appliances supply clean water and liquid with minor impurities, industrial models can be used to work with fairly aggressive media.