Inverter welding is a proven method of joining stainless steel products. It is recommended to everyone for welding.

Many owners of dachas and garages can not do withoutinverter type welding machine. But everyone is wondering whether it is possible to weld stainless steel parts. The answer is simple. If all the necessary requirements are met, then it will be done.

Inverter welding is carried out using special electrodes. For example, OZL-8. This type of electrodes is convenient for welding stainless steel parts with markings:

• 08Х18Н10Т;

• 08Х18Н10;

• 12Х18Н9.

Using special electrodes, you can avoidintercrystalline corrosion. A welded seam is obtained when special electrodes are used. He will be able to withstand the impact of acid and alkaline environment, and not just atmospheric phenomena.

Welding of stainless steel inverter is done with the help of piece electrodes. They are designed for welding stainless steel (MMA) and for welding in protective gases (TIG).

Welding is carried out using a source of permanentcurrent with a reverse polarity of a short arc. This means that the electrode should have a polarity with a plus sign, and on the welded part with a minus sign.

The inverter for argon-arc welding is used,to avoid oxidation or ozonization. Before starting work, it is necessary to thoroughly clean the entire surface of the material from contamination. In any spatial position, the direction of the weld can be located.

When choosing an inverter, consider the following nuances:

1. The device should work at increased and lower voltage. Deviations of the supply voltage are allowed within 20%.

2. The temperature range is very important. Some models can not operate at low temperature. The inverter EN 60974-1 is capable of operating in the range from -40 ° C to + 40 ° C.

3. For household purposes (welding stainless steel or aluminum) 160 amperes at the output will be enough. But for professional work it is better to use apparatus with a power of more than 200 amperes.

Study the passport carefully.See if the inverter is suitable for your purposes. It indicates the type of electrodes that fit this model. Do not forget that the type of welding depends on the grade of steel and its purpose.

Welding inverter has many advantages:

1. Increasing and lowering the voltage in the network to 20% does not play a big role.

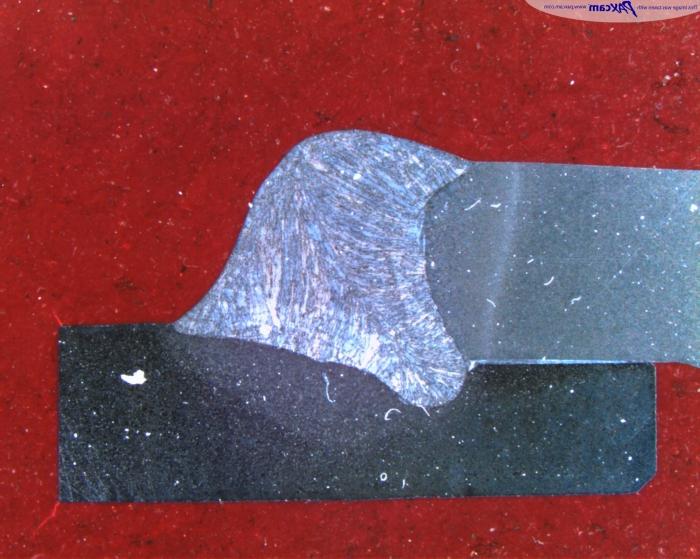

2. Very high quality of the seam.

3. The consumption of electrodes is less, because the level of spattering of metal is very low.

4. Ability to use more versatile electrodes for different types of stainless steel.

If you are the owner of a welding machineInverter type, then you can do all the work yourself. Thus, the cost of electrodes will be directly proportional to the cost of these works. The maximum price for electrodes - 700 rubles per package, but the options are cheaper to find. If you seek help from a welder, then the amount for services will increase at least twice.

Welding inverter is not such an intricate occupation. This is for everyone. The main thing is desire, and you will succeed.