Hot-rolled steel sheet representsa metal product of the simplest geometric configuration, which in modern production is a very popular consumable material. The product has found application in various areas of the economy, in architecture, construction, civil and military aviation, in the manufacture of automobiles, machine-tool construction, the erection of bridges, in decorating and design.

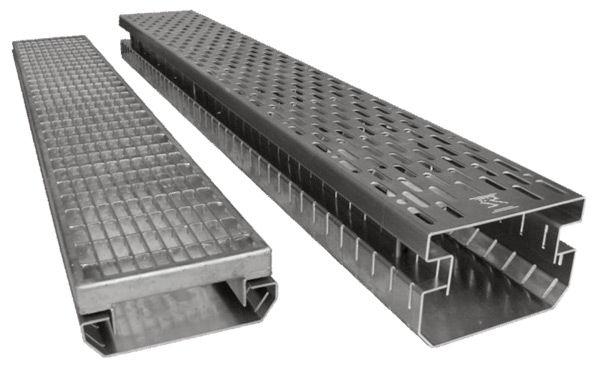

The popularity of this product is largelydue to a rather low price for a hot-rolled sheet. In most cases, the product is purchased for further processing. For example, the metal is pulled out and cut through, thus obtaining a perforated exhaust sheet, from which street fences, fittings, stair steps and other products are subsequently made. Qualitatively produced hot-rolled sheet freely maintains rolling, stamping and stretching.

In the manufacture of steel materialsare governed by the requirements of state standards. For the production of hot-rolled steel sheets used hot rolling technology. To create the material, both low-alloy and simple carbon steel is used. Hot-rolled sheet produced by processing the pressure of a metal heated to a high temperature on a calibrated or smooth rolls. Supply of products of this type is carried out in rolls or sheets.

Hot-rolled sheet has the following characteristics.In terms of rolling accuracy, there are two classes of these materials with a thickness of up to 1.2 centimeters. To class A carry products with high accuracy, and to category B - with normal. The mandatory quality characteristics of products include the minimum values of resistance (temporary).

In addition, there is a plate,which is divided into six groups. The first five characterize the production of hot-rolled sheets. The latter category includes products with increased strength. Sheet materials are produced with normal, high and very high flatness.

The most complex steel production processHot-rolled sheets begin with the arrival of blanks (slabs) at the metal-working enterprise. These components are usually cast from carbon or alloy steel.

In the next stage, slabs are sent to the rollingmill, with which steel billets give the desired size and shape. In appearance, hot-rolled sheet may differ depending on the profile and rolls used in the production. Hot steel gets the necessary thickness in the process of moving through the rolling mill. At the same time there are two production stages: roughing and finishing. If the cropping of uneven edges was not made, then the hot-rolled sheet is classified in accordance with technical standards as uncut.