Ежегодно из-за коррозии пропадает очень много metal. However, even greater damage is caused by the failure of metal products as a result of corrosion. The costs necessary for the replacement of parts or the maintenance of instruments, automobiles, sea and river vessels, and equipment used in chemical production are many times higher than the cost of the material used to make them.

Significant losses are also indirect.These include, for example, gas or oil leaks from pipelines damaged by corrosion, food spoilage, destruction of building structures and much more. Therefore, the fight against metal corrosion is of paramount importance.

Why is the destruction of metallic materials?

Before turning to the question of what is stainless steel, let's deal with the concept of corrosion and the essence of this process.

Translated from the Latin corroder - corrosion.Slow spontaneous destruction of metals and alloys on their basis, occurring under the chemical influence of the environment, is called corrosion. The reason for such destruction is the chemical interaction (redox reactions) of metallic materials with gaseous or liquid medium in which they are located.

What are corrosion resistant steels and alloys?

Stainless steel and heat resistant steel orTheir alloys are designed to work in corrosive environments at high or normal temperatures. Therefore, the main requirement for materials of this group is heat resistance (resistance to the effects of a gas medium or a pair of high temperatures) or corrosion resistance (having the ability to effectively resist the effects of aggressive factors at ordinary temperatures).

Коррозионная стойкость свойственна металлическим products, on the surface of which a strong passivating film is formed in an aggressive environment, preventing penetration into the deeper layers of the metal and the interaction with them of an aggressive substance.

In other words, stainless steel is steel that is resistant to intergranular, chemical, electrochemical, and other corrosion.

Chemical composition

Metal properties are determined by its chemicalcomposition. When the chromium content of 12-13% steel becomes stainless, that is stable in the atmosphere and chemical environments. Increasing the chromium content to 28-30% makes it stable in aggressive environments.

Among the other elements used foralloying includes manganese, aluminum, titanium, nickel. The most widely used alloys, in which the average nickel content is 10%, chromium - 18%, carbon - from 0.08 or 0.12%, titanium - 1% (12X18H10T - stainless steel, GOST 5632).

Microstructure type classification: austenitic grade of stainless steel

Resistance of this class to corrosiveimpact increases due to the elements of nickel doping (from 5 to 15%) and chromium (from 15 to 20%). Austenitic alloys are insensitive to intergranular corrosion, provided that their carbon content is less than its solubility limit in austenite (0.02-0.03% or less). Non-magnetic, well subjected to welding, cold and hot deformation. Possess excellent workability. This is the best steel for the manufacture of fasteners, welded structures and applications in various industries.

Martensite class

Martensitic grade stainless steelscan be magnetic and have higher - in comparison with austenitic - indicators of maximum hardness. Hardening is achieved by quenching and tempering. Well suited for the production of products intended for use in medium and low intensity environments (for example, a number of food industry products or the production of razor blades).

Ferritic grade

With high corrosion resistance properties of thesegrades are similar to low carbon steel. The average chromium content is 11-17%. Used in the manufacture of household appliances, elements of architectural decoration of the interior, kitchen utensils.

Austenitic-ferritic class

Коррозионностойкие нержавеющие стали данного class differ in reduced nickel content and high chromium content (from 21 to 28%). Niobium, titanium, copper act as additional alloying elements. After heat treatment, the ratio of ferrite and austenite is approximately one to one.

По прочности аустенитно-ферритные стали превышают austenitic twice. At the same time, they are plastic, well resist shock loads, have a low level of corrosion cracking and high resistance to intergranular corrosion. Recommended for use in construction, manufacturing, for the manufacture of products that will be in contact with sea water.

Austenitic-martensitic class

Содержание хрома от 12 до 18 %, никеля - от 3,7 up to 7.5%. Additional elements - chrome and aluminum. Hardened by quenching (t> 975 ° C) and subsequent tempering (t = 450-500 ° C). Austenitic-martensitic stainless steels are well welded and have high mechanical properties.

Stainless steel: price (factors affecting the formation)

The composition of corrosion resistant metals includesexpensive alloying elements, such as chromium, nickel, titanium, molybdenum. Their cost is decisive in pricing. Since other grades (carbon, structural, ball bearing, tool, etc.) contain these elements in much smaller quantities, compared to them, the cost of corrosion-resistant steels is always higher. However, the price may vary depending on market conditions and costs required for the production of stainless steel.

Mechanical properties

Grades of corrosion-resistant steels must have mechanical properties that meet the requirements of established standards for manufacturing. These include:

- maximum Brinell hardness (HB);

- relative extension (%);

- yield strength (H / mm2);

- tear resistance (H / mm2).

After production, each batch (smelting)commercial products are checked for compliance with the mechanical properties and microstructure of the steel grade GOST. The results of laboratory testing of samples are indicated in the certificate for manufacture.

Steel Grade System

In various countries around the world produced an extensive range of alloys and steels. At the same time, there is no single international labeling system.

In the United States of America acts immediatelymultiple labeling systems. This situation, due to the presence of a large number of standardization organizations (AJS, ANSI, ACJ, SAE, AWS, ASTM, ASME), creates certain difficulties for partners, contractors and customers of metal products of American manufacturers from other countries.

In Japan, steel is marked with letters and numbers.indicating their group (low-alloyed, high-alloyed, special-purpose alloys, medium-alloyed, high-quality, high-quality, etc.), its serial number and properties of the metal.

In the countries of the European Union, designations are governed by the standard EN 100 27, which determines the order in which the name and sequence number are assigned.

In the Russian Federation, thethe times of the Soviet Union alpha-numeric system, in accordance with which are designated steel grades. GOST prescribes to indicate each alloying chemical element that is part of the metal, with a capital Russian letter.

For manganese it is G, silicon - C, chromium - X, nickel - H, molybdenum - M, tungsten - B, vanadium - F, titanium - T, aluminum - U, niobium - B, cobalt - K, zirconium - C, boron - R.

Цифры, следующие за буквой, указывают содержание alloying elements in percent. If the composition of the steel contains less than 1% of the alloying element, then the figure is not affixed, with a content of 1 to 2% after the letter they put 1. The two-digit number indicated at the beginning of the mark is necessary to designate the average carbon content in hundredths of a percent within the grade composition.

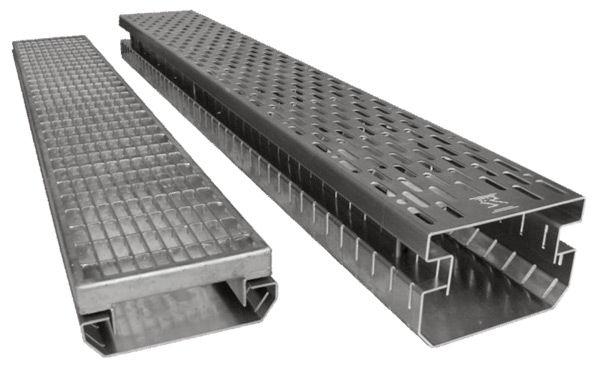

The range of products manufactured from stainless steel

Stainless steel is used to manufacture the following products:

- heat treated etched and polished sheets;

- heat-treated non-etched sheets;

- thermally raw and non-etched sheets;

- warm, cold and hot-rolled seamless pipes;

- steel hot-rolled strips of general purpose;

- calibrated hexagons;

- stainless circles;

- stainless wire (thermally treated and cold-drawn);

- castings with special properties;

- forgings;

- other types for which GOSTs and technical instructions (TU) are developed.

Application area

Being one of the best examples of strength,aesthetics, resistance to the effects of destructive corrosion and high temperatures, suitability for recycling and durability of operation, possessing excellent surface finish quality meeting all sanitary and hygienic requirements, stainless steel is widely used in almost all spheres of economic activity.

Stainless steel is in high demand inpetrochemical, chemical, pulp and paper, food industry, in the construction industry, electric power industry, shipbuilding and transport engineering, in the fields of instrument-making and environmental protection.

Efficiency and durability of productsmade of stainless steel, is determined by the correct choice of its class and brand, understanding of the physicochemical properties and structure of the microstructure. Using metals that are resistant to the damaging effects of corrosion, in strict accordance with their properties, we are able to take advantage of all the indisputable advantages of modern technology.