Natural rubber has many analogs, and one ofisoprene rubber is considered the most large-tonnage. The industry produces the most diverse types of these products, differing in both the properties and the type of catalysts that have been used - lithium, complex, and the like.

How is the rubber

Isoprene rubber is synthetic, itstereoregular, and get it through the polymerization of isoprene, placed in an inert solvent with a complex catalyst. This is done, for example, SKI-3. The polymerization of isoprene in the solution must be continuous, for this purpose there are batteries of four to six polymerizers, which are cooled by brine.

The monomer in the mixture is concentrated to twelve -Fifteen percent, then the degree of conversion will reach ninety-five percent, and the duration will be two to three hours at temperatures from zero to ten degrees Celsius. If it is necessary to obtain high molecular weight isoprene rubber, the purity of the reagents used in the polymerization is very high.

Stabilization and Drying

To protect the polymer from oxidation, you need itstabilize using a mixture of phenylenediamine and neozone, which must be introduced into the polymer as a solution or aqueous suspension. To isolate the isoprene rubber from the polymer as a crumb, it is necessary to mix the polymer with steam and water, then add additives that prevent agglomeration (clumping). After that, it is necessary to drive off the solvent. Now it is necessary to carry out the processes of degassing, separating the crumbs from water and drying in worm machines and belt dryers. At the end of this process, the production of isoprene rubber can be considered complete.

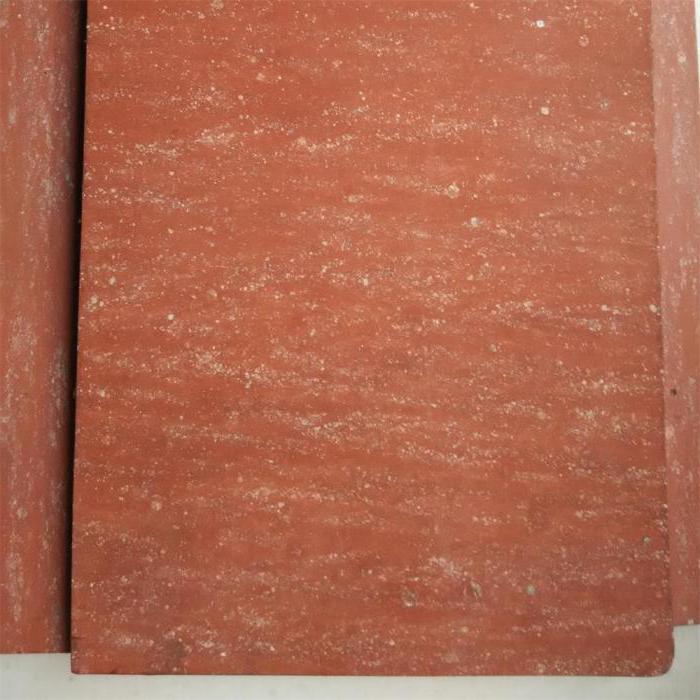

Now it is his briquetting onautomatic installations under the press. Mark SKI-3 - synthetic isoprene rubber, which is available in briquettes of thirty kilograms each. The briquette is wrapped in plastic and placed in a four-ply paper bag. This film is quite well processed at the same time as the content, which is isoprene rubber, its properties with mixing temperature completely allow the polyethylene to soften and mix it with the main mass in the rubber mixer.

Structure

Every rubber that is producedindustry has its own characteristics and properties inherent only in this variety. Some rubbers have good mechanical strength, others have chemical resistance or gas tightness, some have no fear of changes in temperature, and so on. The properties of individual synthetic rubbers surpass natural in many ways and many times. Only the elasticity of natural rubber has not yet been surpassed, and this is an essential feature for products such as aviation or car tires.

При эксплуатации они всегда испытывают огромную deformation - and stretching, and compression, which causes intermolecular friction, heat and loss of qualities. That is, the higher the elasticity of rubber, the more durable the product. It is for this reason that natural rubber has not yet come out of use, and that it is used for the production of tires for high-speed and heavy aircraft and automobiles. Natural rubber is an isoprene polymer, which is why scientists are so great at making isoprene rubber an analogue of natural rubber.

Formula

Natural rubber mining resources are very limited. Normal, obtained in nature, rubber has the formula C5H8, как оказалось, она абсолютно идентична molecular formula of isoprene, which is formed when rubber is heated, in its decomposition products. The task is to find a fairly affordable way. And isoprene rubber is obtained by the polymerization reaction, and here it is important to correctly construct the course of this reaction. Polymerization is as follows: nCH2 = C (CH3) - CH = CH2 ----> (-H2 - C (CH3) = CH - CH2) n.

The most promising method so far is the method of catalytic dehydrogenation of isopentane, which is released from petroleum gases. Pentane can also be the starting material for the production of isoprene: CH3-CH2-CH2-CH2-CH3because when heated and with catalysts italso turns into isopentane. There is also a method of polymerization, in which the reaction of obtaining isoprene rubber is built in such a way that rubber is obtained, which is very similar in its structure to natural and, therefore, has the same excellent properties.

Isoprene

Isoprene is an unsaturated hydrocarbon,belonging to the diene series. It is a volatile, colorless liquid. The smell is very characteristic. Isoprene rubber is a natural monomer, since the residue of its molecule has entered many other natural compounds — isoprenoids, terpenoids, and the like. It is dissolved in organic solvents. With ethyl alcohol, for example, can be mixed in any ratio. But in water it dissolves poorly.

But it easily forms a structural link.isoprene rubber during polymerization, due to which isoprene gutta-percha and rubbers are obtained. Isoprene can also enter into different reactions during copolymerization. In industry, it is indispensable, since it is used to synthesize rubbers, medicines, and even some fragrances. In our country, the production of synthetic isoprene rubber has been developing for a long time, and is approximately twenty-four percent of world production.

History

The first isoprene was obtained in 1860 by the methodpyrolysis from natural rubber. Pyrolysis is thermal (at high temperatures) decomposition of many inorganic and organic compounds under conditions of oxygen deficiency. Later an isoprene lamp was invented — an electric, with a heated coil, with which turpentine oil was thermally decomposed in laboratories.

World War II brought a hugethe need for isoprene rubbers, and therefore isoprene learned to produce on an industrial scale through the pyrolysis of limonene. Still, isoprene was too expensive for the mass production of synthetic rubbers. The situation changed when a method was found to obtain it from oil. Then began the rapid development of technology for the polymerization of isoprene.

Role in the economy

The most important thing in planning the production of such a product as isoprene rubber is to choose the right location because it will have to deliver fraction C fractions.5 to the destination of several companies that carry out the cracking. In second place in importance is the consideration in the plans of the place of disposal of the remaining hydrocarbons from fraction C5.

By the early nineties of the twentieth century, Western Europe was producing about eighty-five thousand tons of dienes.5of which forty four thousand tons wasdimerized cyclopentadiene and twenty three thousand tons is isoprene. The rest - about fifteen thousand tons - were piperylene. Ten years later, world production of isoprene increased to eight hundred and fifty thousand tons per year.

Properties

In standard conditions, isoprene, as it was alreadyit is said that it is a volatile colorless liquid, which is almost insoluble in water, but miscible in any ratio with diethyl alcohol, standard, benzene, acetone. Isoprene is able to form azeotropic mixtures with a variety of different organic solvents. When considering the data of spectroscopic studies, it can be seen that already at fifty degrees Celsius most of the isoprene molecules adopt a stable s-trans conformation, only fifteen percent of the molecules are in the s-cis conformation. Between these states, the energy difference is 6.3 kJ.

The chemical properties of isoprene represent it astypical conjugated diene, which enters into the reaction of substitution, addition, complexation, cyclization, telomerization. Active in reaction with electrophiles and dienophiles.

Application

Основная часть изопрена, который производится в currently used in the synthesis of isoprene rubber, similar in structure and properties to natural rubber. It is used especially for tire production. There is another product of the polymerization of isoprene - polyisoprene, which is used much less, because it has gutta-percha properties. For example, wire insulation and golf balls are made from it. Isoprene rubber is used for the manufacture of various rubber products, which combine natural and other synthetic rubbers.

For example, to reduce stickiness, addbutadiene-methylstyrene rubbers; moreover, fatigue endurance increases if the deformations are multiple. Nitrites add ozone resistance and resistance to heat aging. Thus, observing the complex of technical properties, isoprene rubbers perfectly manifest themselves when using conveyor belts, suction or pressure hoses, when lining the shafts of machines, in the manufacture of footwear, medical and other products.

Environmental hazard

Isoprene easily explodes and ignites.In high concentrations in the body can lead to paralysis and death. This mainly occurs at atmospheric saturation, and therefore the metabolism occurs in the respiratory system, when isoprene is converted to epoxides and diols.

A high concentration is considered fortymilligrams per cubic meter is the maximum dose. Small concentrations of isoprene in the air can have a narcotic effect on humans, irritating the eyes, skin, respiratory tract and mucous membranes.

Biology

Modern scientists have found that isoprene vapor releases almost all plants into the atmosphere. The global volume of phytogenic isoprene is approximately estimated at (180-450).1012 граммов углерода в год.This process is accelerated if the temperature of the air approaches thirty degrees Celsius, as well as if the intensity of solar radiation is high while photosynthesis is already fully saturated. Isoprene biosynthesis is inhibited by fosmidomycin and compounds of a number of statins. Why plants do this is not fully understood. Isoprene may give them extra resistance to overheating. In addition, it is a catcher of radicals, which means it can protect plants from reactive oxygen species and from exposure to ozone.

Scientists also suggest that isoprene synthesisforces us to constantly expend NADPH and ATP molecules, which the plant produces during photosynthesis. This means that the release of isoprene protects from photo-oxidative damage and re-recovery if the lighting is excessive. The disadvantage of this protection mechanism may be one: carbon, which is so hard extracted in the process of photosynthesis, is spent on the release of isoprene. Scientists did not stop at the plants and found out that the human body is also able to produce diene hydrocarbons, and isoprene among them occurs most often.