Мероприятия по убою скота и дальнейшей processing of meat obtained is a complex and multi-stage process. The technologies involve the use of specialized equipment, which includes units for cooling, storage and preservation of carcasses. Modern machines and processing lines allow you to organize a virtually waste-free production with the recycling of secondary raw materials. As a rule, equipment for slaughterhouse livestock is used to complete individual premises. But lately, modular workshops have also gained popularity, in which technical equipment with the necessary slaughter units is already provided. Such objects are slaughter points, which are characterized by high functionality and the possibility of minimizing costs.

Stunning Equipment

For stunning special boxes are used.As a rule, they are designed to work with pigs. Stainless steel is used as material for construction. Standard dimensions of such boxes have the following indicators: 162 cm in length, 175 cm in height and 75 cm in width. Such equipment for slaughter of pigs has a mass of not more than 200 kg, allowing stunning individuals weighing up to 140 kg. Boxing is performed as follows:

- Pigs are introduced for slaughter, after which the lid closes.

- By means of special forceps stunning is made.

- Lever box removed from the lock.

- The carcass automatically gets from boxing to slaughterhouse.

The advantages of such models for stunning worthinclude lack of care. Of course, after each event, thorough cleaning should be done, but because of the simple design, these actions do not cause any special problems. After the stunning operation, equipment for slaughterhouse of another type is involved. In particular, technical means may be used for the primary processing of livestock.

Primary processing workshops

Мелкие мясоперерабатывающие предприятия обычно не can afford the supply of complete units, designed to perform each processing cycle with high performance. In such cases, the best option is the primary processing complex. As a rule, machines are concentrated in such complexes, through which a mini-slaughter is organized. This type of equipment allows for a full processing cycle. Again, the function of machines is implemented with the expectation of minimizing costs with the use of non-waste technology. In other words, the company recycles all secondary products. From switching to such power, many are stopped by low productivity and unsatisfactory functionality. But this does not apply to modern lines. First, the availability of automatic machines and machines accelerates the pace of processing. Secondly, slaughterhouses are supplied with equipment of different types, which should be considered separately.

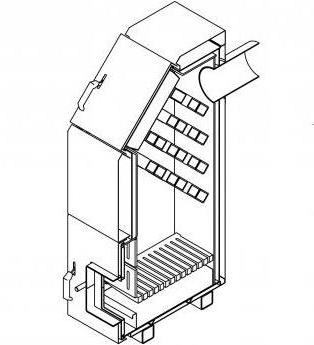

Grade mini-slaughterhouse

В оснащение комплексов переработки включается several types of equipment. In fact, each machine is a small line, fulfilling its strictly processing function. For example, equipment for slaughterhouse "cattle" in the integrated processing system is represented by the following machines:

- Stunning compartment with head trap and feeder.

- The skinning platform of lifting type with a drum.

- Nutrovochnaya base with a receiver for the intestines.

- Lift for quartering.

- Device for placing the carcass on the suspension paths.

- Track scales.

- Cooling tunnel

- Weight (usually supplied as an option).

- Band-saw.

Разумеется, комплектация может включать и другие units, but in this case the standard set of means of primary processing is considered. It is important to note the similarity of the line with industrial offices for slaughter. Even in the minimum configuration, the equipment for the “KRS” slaughterhouse allows you to perform not only basic operations, but also auxiliary procedures — for example, those associated with the same waste treatment.

Characteristics of the complex "KRS"

The modular line can be designed to work withvarying degrees of productivity, allowing for the slaughter of livestock at an average speed of up to 5 heads per hour. Such a complex "KRS" will have the following characteristics:

- Weight - 14 tons.

- Dimensions - 1220x244x554 cm.

- Network requirements - 380 V on condition of connection with dry contact.

- Power consumption in the summer - 24 kW / h.

- Power consumption in winter - 28 kW / h.

- Water pressure - a minimum level of 2 atm.

- The connecting size of a sewer drain - 11 cm.

Модульные комплексы формируются из тех же components as traditional meat processing plants. Modern equipment for the slaughter of livestock and primary processing is closely connected with devices and devices for the removal of hides and skinning. These are high-tech machines that are equipped with auto-correction sensors, reliable weights and other useful options.

Slaughterhouse facilities technical support

As a rule, there are four departments in whichoperations are carried out on stunning, slaughter and further processing of meat and waste. The main compartment includes the stunning box already mentioned, the slaughterhouse itself, the electrical silencing device, and the boom box. This is followed by the site where intestinal waste is processed. Its equipment includes units for intestinal wringing and technological table. Some enterprises also provide offices in which food is cooked. Here are installed special vats, carts, the same technological table and food kettles.

Almost at every stage of processing possiblefat formation. Various devices may be provided for its collection, but the most effective solution would be to organize a department for draining fat with appropriate machines. It is worth noting that the equipment for the slaughterhouse, divided into several departments, lasts longer and requires less time for maintenance. But in practice it is possible to achieve these advantages only under the condition of rational zoning of space in the enterprise.

Slaughter Equipment Owner Reviews

Usually reviews of famous car manufacturersare supportive. The owners of the equipment note high functionality, durability and performance. By the way, modern models are supplied with all kinds of electronic systems and automated devices. Such equipment for slaughter of livestock, undoubtedly, increases the speed of work and quality, however in case of breakage it is necessary to prepare a serious amount for repair work. And yet users of such lines talk about the convenience of operating specialized technological equipment. But it is expensive and requires a more careful approach to the content.

Reviews of modular workshops

Complex lines have advantages in the formcompactness, optimization of processing and, in some cases, they are economical in operation. However, according to the owners of the modular workshops, the equipment for the slaughterhouse is closely connected with each other and if one device breaks down, the whole cycle stops. However, such phenomena depend on the equipment and configuration of a specific mini-slaughterhouse. In addition, such risks are covered by block mobility and space management. If we talk about the cost, then in some cases it exceeds the cost of equipping an ordinary workshop.

How much does the equipment cost?

The price corridor is quite extensive, sinceequipment varied. The lower level is represented by individual devices and fixtures. This is the initial equipment for slaughter of livestock, the price of which can be 30-50 thousand rubles. If we talk about accessories in the form of hooks and cleaners, they are estimated at 5-10 thousand rubles.

Очевидно, что модульные линии убоя оцениваются в large amounts. In the middle range, we can talk about 2-3 million rubles. However, it all depends on the configuration, additional devices, functionality and performance of the mini-workshop. For example, the most expensive is considered to be automatic equipment for slaughterhouse - in this case the prices increase to 3-3.5 million rubles. for one shop.

Conclusion

As meat producers point out, as wellentrepreneurs whose activities are related to this area, the technical organization of slaughter does not present any particular difficulties. The main thing is to determine the specific tasks of the enterprise, find the appropriate premises and calculate the communication support of the line. Difficulties may arise due to the unprofitability of the business. It is important to consider not only the equipment for the slaughterhouse, but also the products that will be produced with its help. No wonder many manufacturers point out the importance of waste-free enterprise. If you correctly calculate the power of the slaughterhouse, the range of possible operations and arrange the conditions for the proper storage of raw materials, then the probability of success of such a business will increase significantly. But these questions should be considered even before the money is invested in the equipment, be it individual machines or a fully equipped modular line.