Despite the growing popularity of cars withautomatic transmission, classic mechanics are still held in high esteem by many drivers. It is more reliable than automatic transmission. But during operation, the driver is constantly forced to work with the clutch pedal. This causes some inconvenience, especially in traffic. So there was a hydromechanical transmission. The principle of its operation and the device will be considered in our today's article.

Characteristic

Those drivers who do not want to work withclutch, give preference to this particular transmission. Hydromechanical gearbox performs several functions at once. It combines a clutch and a classic box.

About construction

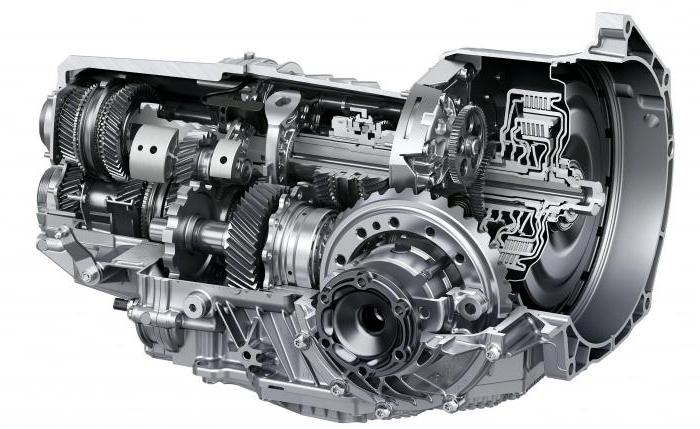

The device hydromechanical gearboxsuggests the presence of a hydraulic transformer. This element, depending on the design features, can be two-, three- or multi-shaft. Now manufacturers use a planetary automatic hydromechanical transmission.

How does the gearbox work

On trucks and large buses more oftenMostly used multi-power transmission. In order to shift gears, multi-plate clutches are used here. For their work requires lubrication. Hydromechanical gearbox oil differs significantly in consistency from the "mechanics". In the latter case, it is more dense. In order to include the first and rear speeds in fluid mechanics, gear couplings are used. This design allows the most smooth transfer of torque from the flywheel to the wheels.

Planetary

Now it is a more common hydromechanical gearbox.

How does the planetary gearbox

Her work algorithm is extremely simple.The gears are shifted to planetary hydromechanical transmission using friction clutches. Also, to smooth shocks when switching to lower, use a special brake band. It is during the operation of the “brake” that the torque transmission force decreases. But at the same time, the speed switch is smoother than that of the analogue counterparts.

The basis of the planetary transmission is a hydraulic transformer. This element is located between the engine and gearbox. HDF consists of several components:

- Gear wheel.

- Pump.

- Turbine.

People call this element a “bagel” because of its characteristic shape.

Features of the design of the planetary gearbox

Planetary hydromechanical gearboxconsists of a drive shaft, which is an articulated gear. There are also satellites rotating on separate axes. These elements are introduced into engagement with the internal teeth of the box and ring gear. The transmission of torque is due to the action of the brake band. It inhibits the ring gear. As the car accelerates, their momentum grows. Involved the driven shaft, which perceives the transmission of torque from the master.

About efficiency

As for the efficiency, it is an order of magnitude lower than on the main gearbox.

Service and repair of hydromechanical gearbox

When operating this transmission, it is necessarymonitor the level of oil. This fluid is working here. It is oil that uses turbines to transmit torque. On the mechanical boxes, it simply lubricates the friction gears. Manufacturers recommend changing the oil on the hydromechanical boxes every 60 thousand kilometers. It is worth noting that the design of such a checkpoint has its own filter. It also changes when this time is reached. Operating at a low oil level threatens to slip and overheat the transmission.

How to extend the resource

To increase the lifetimehydromechanical box, it is necessary to monitor the oil level. If it is not enough, the box overheats. Operating temperature should not exceed 90 degrees. Modern cars are equipped with an oil pressure sensor. His warning lamp lit, you should not ignore it. In the future, this may cause breakdown of the torque converter.

Conclusion

So, we found out what constituteshydromechanical gearbox. As you can see, with proper maintenance, it will be as reliable as mechanical. In this case, the driver does not have to constantly squeeze the clutch.