The torque of the cylinder head VAZ 2112 (16 valves) is veryimportant because with an uneven head installation deformation occurs. This leads to the fact that after disassembly it will be necessary to grind at least 2 mm from the surface of the head of the block. If you follow all the tightening torques, then you will not have to sharpen the head, and if you need to do this, then no more than a quarter of a millimeter.

Head structure

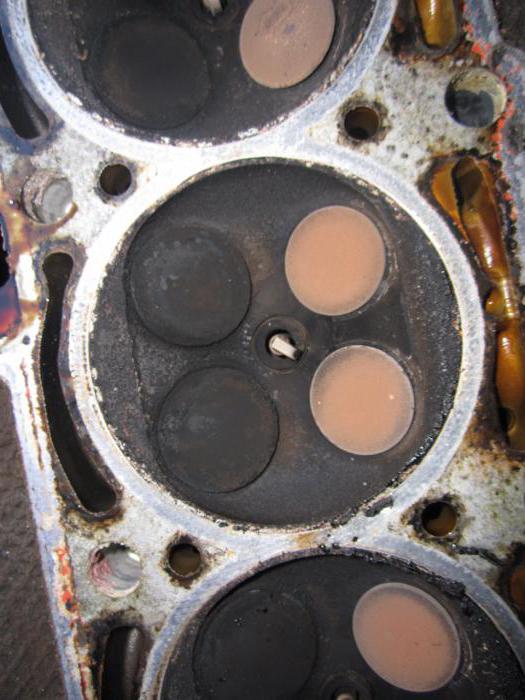

The 16-valve engine uses a head unit in which the following elements are located:

- Two camshafts. They are with five supports, cast from cast iron, each has 8 cams. Install instead of the intake camshaft exhaust (and vice versa) can not.

- 16 valves. They are mounted on guide bushes.

- Directly on the head of the block are installed saddleswhich are in contact with the valve plates.

- Hydraulic expansion joints in the amount of 16 pieces.

Camshafts are mounted on supportsCylinder head. Compliance with the torque of the cylinder head VAZ-2112 (16 valves, 1.5 liters) allows for the normal functioning of the engine. Also, this will avoid costly milling of the surface after the next dismantling of the head.

Preparing to replace the cylinder head gasket

When removing the head unit, be sure to changegasket - it can not be reused, as this will lead to breakdown. It also needs to be changed if antifreeze or engine oil leaks in the area where the block and head connect. Often leaks appear as a result of damage to the head itself due to excessive heating. If you do not observe the tightening torque of the cylinder head bolts of the VAZ-2112 (16 valves), the gasket may be damaged and liquids may leak.

Preparatory work before replacing the gasket:

- Disconnect the negative terminal from the battery.

- Install the piston in the first cylinder to the position corresponding to the top dead center.

- Completely drain the liquid from the cooling system - to do this, first unscrew the plug at the bottom of the radiator, then in the engine block.

- Be sure to relieve pressure in the fuel system - for this purpose there is a special fitting in the rail.

- Remove the exhaust pipe mounting nuts from the exhaust manifold.

- Remove the thermostat.

- Unscrew the nut that secures the bracket to the fluid pump pipe.

- Loosen the nut that holds the bracket to the manifold (exhaust). After that, take him away so that he does not interfere with the work.

- Disconnect the block of wires from the oil sensor and on the engines of the VAZ-2111 modification, you need to unscrew or loosen the nuts that secure the supporting and supporting brackets.

Removing the cylinder head

After the preparatory work is necessary to make a complete removal of the head. For this, the following manipulations are performed:

- Disconnect the white block from the KDPV, for this you will need to squeeze the plastic latch.

- Remove the plastic decoration panel and the metal cover from the head of the block.

- Remove the timing belt. To do this, unscrew the nut of the tensioning roller and remove it completely.

- The camshaft pulley must be fixed with a screwdriver - try not to allow turning.

- Remove the camshaft bolt and remove it completely.

- Similarly removed the second camshaft.

- Unscrew ten bolts that secure the head to the block.

After that, you can completely remove the cylinder head. The torque of the cylinder head VAZ-2112 (16 valves) under the turbine is the same as without it.

Features of the valve system

On the VAZ-2112, the valve design is very similar to that used in the VAZ-2110 engine. Only they have a diameter of rods and plates slightly smaller. Dimensions:

- The inlet valve is a plate with a diameter of 29 mm, the rod is 6.975 mm.

- The exhaust valve is a plate with a diameter of 25.5 mm, the rod 6965 mm.

A spring is installed on each valve;length without load - 38.19 mm. With a load of 240 Newtons, it decreases to 32 mm. If you act on a spring with a load of 550 Newton, its length is reduced to 24 mm.

Hydraulic Pushers

Valves are driven by cams.on camshafts and hydropushers. These elements are located inside the guide holes. By means of hydropushers it turns out to automatically eliminate gaps in the mechanism of valves. Therefore, when operating a vehicle, it is not necessary to adjust the valve's thermal clearances.

To hydropushers worked in normalmode, from the lubrication system comes to them oil. It is served on special channels in the engine block and cylinder head. Oil passes through these channels and to lubricate the necks on the camshafts. There is a valve in the channel through which the oil does not drain from the top after the engine is turned off. This allows you to maintain the system in normal mode until it stops.

Camshafts

When repairing the head must be checkedcamshaft condition. When the assembly is carried out, follow the instructions and maintain the torque of the cylinder head VAZ-2112 (16 valves). On the "Priore" is set such a motor - it is quite powerful, has excellent characteristics and does not require frequent maintenance. Two camshafts drive the intake and exhaust valves.

Camshafts rotate in specialnests that are directly in the head. The difference between camshafts is that there is a small belt on the intake. It is located near the very first support. To prevent axial movement, there are resistant flanges - they are located on both sides of the support in front. There are self-tightening glands on both camshafts ahead.

How to repair

In order to repair the unit's voice, you need the following tools:

- Device for compressing valve springs. You can use as a "shop", and improvised. The main thing is to be comfortable to work.

- Device for removing the valve seals.

- Mandrel in the form of a tube for installing caps.

- Keys on "10", hexagons, tweezers and screwdrivers.

Perform such manipulations:

- Carry out all actions on removal of a head and camshafts.

- Remove all valves with a special device.

- Remove the valve seals.

- Проведите замену и притирку клапанов.It is necessary to change the valves in the event that there are damages - burnouts, geometry violation. Be sure to sign on which sockets the valve is rubbed in - otherwise tightness will be broken.

- Collect all valve drive mechanisms - hydropushers, springs, lock them with breadcrumbs.

Все действия по сборке узла проводятся в обратном order, you only need to take into account one feature: stick to the recommended values of the torque of the cylinder head VAZ-2112 (16 valves). The photo shows the sequence of tightening.

How to tighten the cylinder head bolts

Be sure to tighten according to the scheme given in the article. In order to tighten the bolts, you need to perform a few simple steps:

- Install a new head gasket, place it on the centering bushings.

- Install the head and bait its mounting bolts.

- You begin to tighten with a torque of 20 N * m. If the scale is in "kgf / m", then divide by 10.

- In the second run you need to tighten all the bolts on the scheme at 90 degrees.

- For the third call, they turn another 90 degrees.

Bolts whose length is 95 mm andmore. In general, the procedure is quite simple, but the presence of a torque wrench is required - without it, it is impossible to withstand the correct torque of the cylinder head of the VAZ-2112 (16 valves).