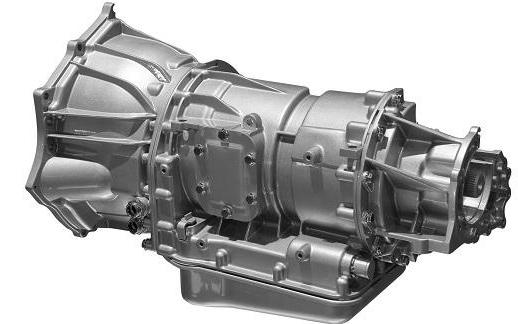

PPC is essentially the main componentcar, because it is impossible to imagine it without a gearbox. Like any part of the car, it can break. Most motorists, faced with this problem, perceives it as a sentence. Due to the fact that the gearbox is a complex structure, it must be repaired by a specialist, who has many years of experience in the service station. But before you try to repair it yourself at the GAZel checkpoint, you should watch the car for some time.

Problem Switching

The root cause: the ingress of air into the hydraulic drive or the lack of fluid in the main cylinder.

The problem is solved by:

- tightening the locking bolts;

- deburring the burrs formed on the teeth of the couplings;

- buying a new gear lever.

Violation of synchronicity when the gearbox is turned on

One of the most common problems, the consequence of which is a crash when changing gears.

Solution of the problem: replacement of the spare part of the blocking ring with its simultaneous lapping to the gear.

The inclusion of transfers in random order is the mosta serious and terrible problem, the result of which can be the emergence of a wedge, which often leads to the creation of an emergency on the road. Moreover, the greater the speed of the machine, the more serious the problem. In the event of its occurrence of CAT requires urgent elimination of deficiencies and repairs.

Solution to the problem:

- replacement of parts that have served their shelf life;

- the acquisition of a new, better spring retainer;

- check the tightening of the nuts, and in the case of loosening - holding the tightening.

Unusual noise in the gearbox, something resembling a crash

Solution to the problem:

- bearing change;

- adding oil to the crankcase to the desired level;

- at failure or deterioration of gear teeth - their replacement;

- Alignment of the clutch housing and the crankshaft.

Repair gearbox ("Gazelle-2705" including) can be made independently.

Gearbox ("Gazelle") do it yourself repair neededIn case of oil leakage, the wear of the oil seals or bushings is the culprit. Sometimes the root cause of this problem is damage to the gaskets or depressurization of plugs and plugs.

The solution may be topping up or changing the oil. In other cases, the situation may be corrected by replacing the gearbox. "Gazelle" is repaired in this case in one light day.

If the transmission fails along the way, one way or another it is necessary to repair the GAZel gearbox with your own hands.

Step-by-step actions: restoring the transmission with your own hands

1. Installing the car in the inspection pit in order to provide access to the main parts.

2. Disconnect the gearshift lever from the transaxle.

3. Drain the oil.

4. Separating the box from the drive shaft.

5. Disconnecting the cable from the wire that turns off the light after reversing.

6. Disconnecting the speed sensor when there is no cable.

7. Unscrewing the bolts that fasten the cylinder and lifting it, without disconnecting it from the pipeline.

8. Removing the clutch fork.

9. Detaching the muffler bracket.

10. Removing the rear support.

11. Detachment of the brackets of the side members with the cross member.

12. Screwing the nut studs in the direction of the engaging crankcase.

13. Removing the gearbox and the bearing disengaging the clutch.

At this removal procedure is over. In order for the diagnostics of the gearbox ("Gazelle 33020" and "Sobol" as well) to be of high quality, it is necessary to clean the gearbox components.

Breakdowns that can be detected:

- poor contact rear sensor;

- bearing wear;

- pressure in the crankshaft of the nose play;

- forcing the secondary shaft.

What is the solution to the problem? Replace with:

1. Primary shaft.

2. Secondary shaft.

3. Sensor corresponding transmission.

4. The gland.

5. A set of paronitovy laying.

You decide to repair yourself or with the help of the service station, remember that the diagnostics of the gearbox (“Gazelle Business” is no exception) is the most important procedure.

The second step is testing the box, the duration of which should be no more than a minute.

Positive test results are in the case of:

- no crunch;

- extraneous sounds;

- easy gear change.

According to statistics, such a procedure as diagnostics checkpoint "Gazelle" should be carried out after every 300 thousand kilometers.

Contacting the service center is necessary in the case of:

- the appearance of vibrations;

- the presence of noise in the checkpoint.

If you ignore this requirement, PPC can break at the wrong time and lead to large cash costs.

The most frequent violations in the transmission associated with:

- poor repair;

- improper operation;

- untimely service cars;

- normal wear and tear.

Timely troubleshooting measures in the transmission will give you the opportunity to have another 300 thousand km of quiet ride.

DIY repair gearbox

"Gazelle" and its transmission can be repaired only if the failure is not serious.

Consider the subtleties of diagnostics CAT GAZ-53, GAZ-31105, GAZ-3110.

In the absence of the necessary gearbox, you should know that the GAZ-53 is ideally suited for the element from the GAZ-66.

The diagnostics of the GAZ-31105 gearbox allows detecting and preventing failures in the car, described below.

Neutral Noise

Cause:

- bearing deterioration of the primary or secondary shafts;

- breakage of the pinion bearing;

- worn or damaged washer adjust the axial play of the intermediate shaft.

Noises at various provisions of the check point

Cause:

- above;

- low gear oil.

The presence of extraneous noise at a particular gearbox position

Cause:

- damage and wear of the gear of the specified gear;

- speed synchronizer breakage.

Transmission dismount from maximum transfer

Cause:

- the transmission mount is too loose;

- the presence of dirt between the crankcase and engine box or the displacement of the box.

Difficulty in switching

Cause:

- the clutch is disabled;

- Damage occurred in the switch gear. In this case, it is necessary to conduct a full inspection of components and replace defective parts.

Loss of gear oil

Cause:

- there is too much oil in the gearbox;

- deterioration of the gland differential or gland drive gear speedometer.

In order to correctly diagnose the PPC GAZ-3110, you must first determine the location of the problem.

The sequence of operations to check the checkpoint GAZ-3110:

1. Trouble shooting by appropriate codes.

2. Carry out a tire pressure test.

3. Test of gearshift and electrical system for compliance with the norm.

4. Analysis of the engine when the vehicle is inhibited.

5. Carrying out road tests of cars for the presence of extraneous noise and vibrations.

6. Carrying out a hydraulic check on the correctness of pressure in highways.

7. Control of gear switching time and check of parts for wear. To a greater extent, this applies to brakes, gears and blocking couplings.